AI in Warehouse Management: Benefits, Challenges, and Use Cases

Any warehouse today must struggle with labor shortages, mismatched demand, and inefficient workflows that stall order fulfillment. Maintaining the pace and managing scaling storage facilities is becoming increasingly complex. Thankfully, a global increase in the level of industrial efficiency is gradually enabled by AI in warehouse management.

Today’s AI systems can predict order jumps and drops, automate inventory tasks, and boost other operations, through automation, monitoring, or analysis in-depth. With artificial intelligence warehouse management, facilities of any size gain dynamic platforms tailored uniquely to their specific operational environments.

How is AI used in warehouse management?

AI warehouse management is the use of machine learning, smart data analytics, robotics, and other intelligent tech to optimize inventory, labor, and space usage in storage facilities. Furthermore, integrating AI in warehouse management enables tools that traditional WMS solutions cannot offer, including:

- Robotics for moving goods, substituting human workers at hazardous lines, and putting hard-to-reach areas to use;

- Forecasting engines for analyzing input, historical data, and BI for predicting seasonal peaks, potential warehouse load, and schedules;

- Dashboards for admins and employees with real-time performance data, warehouse maps and inventories, and instant access to automated hardware.

As such, the use of AI in warehouse management helps tackle the main issues of non-AI WMS — reduce manual tasks, diversify fixed schedules, and optimize hazardous workflows.

AI technologies in warehouse management

Above all else, artificial intelligence warehouse management is enabled by a set of technologies, which include the following.

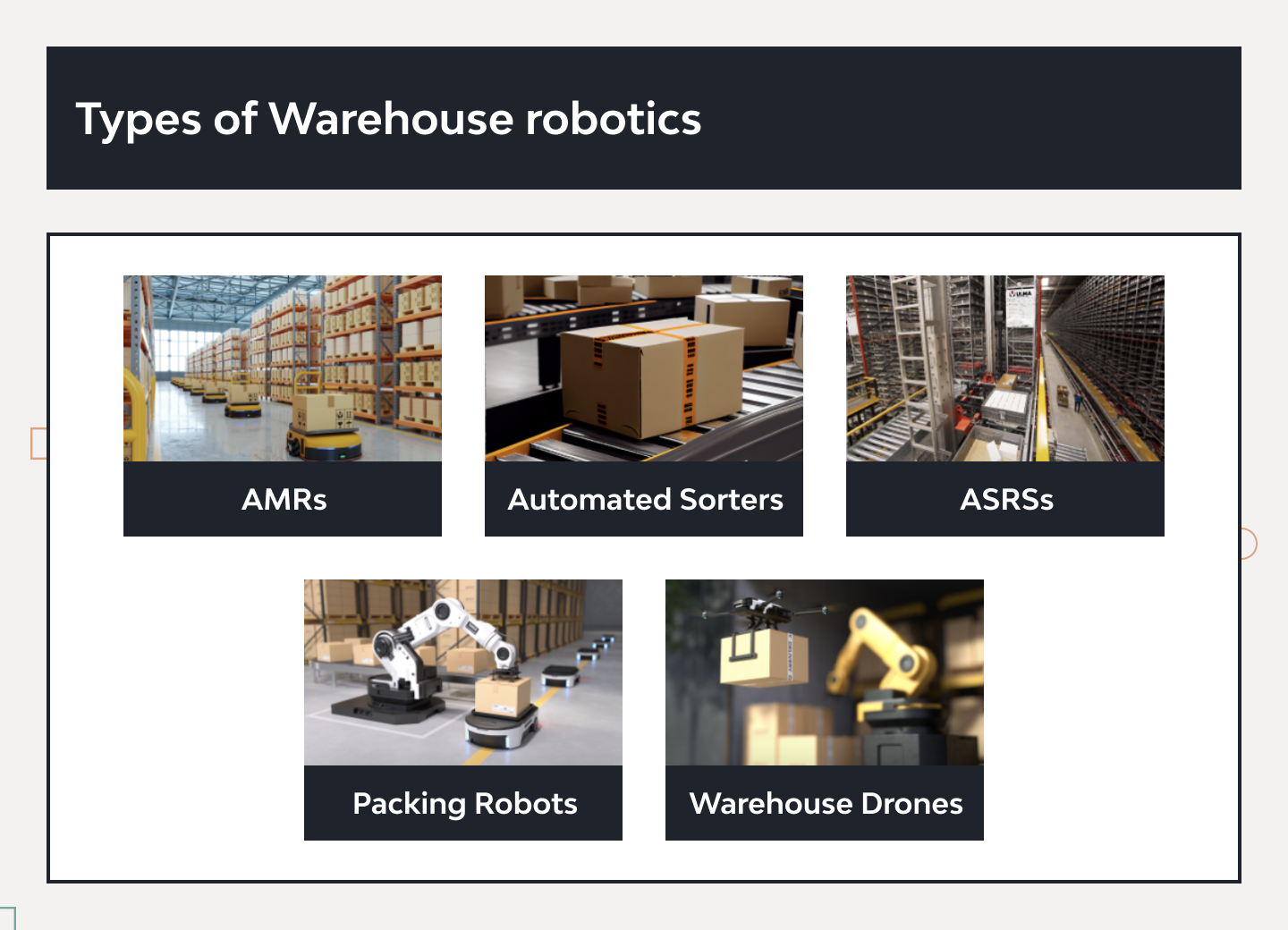

Autonomous Mobile Robots

Or AMRs for short, these self-guiding bots scan the warehouse environments and learn to navigate them efficiently to deliver goods to packing areas or assist pickers. For this, they use advanced sensors, cameras, and ultrasonic arrays.

Larger facilities can set up a fleet of such bots and manage it via a single dashboard. The AMR fleet can also be easily expanded or contracted based on demand just by adding or removing the bots.

Predictive maintenance

Enabling AI for warehouse management, you can gather metrics from conveyors, forklifts, HVAC systems, and storage machinery. By analyzing the metrics like temperature, vibration, and operational load, AI can suggest early warning signs of potential failures.

Thanks to early detection, minor issues can be prevented from escalating. And with fewer emergency repairs, you get lower maintenance expenses and more time saved for other employee tasks.

Smart warehousing

The most common way to leverage intelligent tools in a storage facility is the use of an AI-integrated warehouse management system (WMS). It is a complex platform packed with innovative features and machine learning tools.

For RFID tags and various sensors to work, Internet of Things solutions are also indispensable. An IoT network can help centralize access to AI in warehouse automation while also leveraging the benefits of cloud computing and data platforms that you can cross-integrate.

Computer Vision

Cameras and AI vision models can detect inventory locations, item conditions, and misplaced goods. CV-enabled systems use cameras and image recognition models to track and verify items across the warehouse, even without barcodes or RFID tags.

AI can detect misplaced items, confirm shipments, and monitor packaging quality automatically. Without human errors and at a much higher throughput, too. Combined with robotic systems, the CV allows autonomous machines to handle, sort, and organize goods efficiently as well.

Natural Language Processing

NLP-equipped AI can interpret, extract, and organize information from unstructured data, including invoices, shipping labels, delivery notes, and internal communications. Voice-enabled interfaces can also guide workers through picking and packing tasks.

Then there’s automated document parsing, which eliminates manual entry errors. All the documentation and communications happening between warehouse management systems, logistics teams, and suppliers are synced up as a result.

Intelligent forecasting and predictive analytics

AI algorithms analyze historical demand, seasonal patterns, and supplier lead times. This can be used to forecast stock requirements and optimize inventory positioning. Predictive analytics tools use historical sales data, seasonal trends, promotions, and logistical patterns to generate accurate demand forecasts.

By integrating these insights into warehouse operations, managers can forget about excess inventory. They can also respond faster to market fluctuations, and use AI solutions for order fulfillment automation, making sure there are always sufficient resources in place to meet existing demand.

Benefits of AI in warehouse management

The main benefits of AI in warehouses stem from the variety of powered tools and features, its in-depth analytical capabilities, and focused, human-error-free automation. Namely, you get:

Smarter demand forecasting

The volumes of data accumulated by the warehouse can be fed to an AI/ML model. It can analyze past sales, promos, seasonal trends, and even weather to predict supply and demand with high accuracy. With the resulting suggestions, you can efficiently plan restocks, replenish the most in-demand goods, and avoid both overstocking and shortages.

The latter are especially important — overstocking means waste and excess costs. Product shortage means missed sales opportunities. An AI-enabled warehouse makes your entire supply chain responsive and on-point, keeping the most demanded goods flowing in and the most demanding customers satisfied.

Optimized inventory management

Once integrated with a warehouse inventory system, AI can begin gathering real-time data from RFID tags, sensors, and digital records to provide a view of stock levels. Based on that view, an AI integration can also automatically change reorder volumes, trigger replenishments, and adjust goods’ placement.

With that in place, the turnover of goods in the warehouse is more dynamic. You can see each position running out, and you don’t need as many manual audits. At the same time, employees running the facility gain a clear picture of all processes, flows of goods, and possibilities for optimization.

Predictive maintenance and reduced downtime

ML models can analyze volumes of operational readings from sensors attached to the hardware. You can track vibrations, temperatures, usage, and wear rates. An ML model will run a deep analysis and forecast when equipment may actually fail.

Predictive maintenance is the next-gen evolution that comes after the preventive and reactive approaches. Instead of scheduling maintenance periodically or reacting to failures after the fact, a warehouse can predict an issue, mitigate it during a planned audit, and avoid any excessive downtime.

Faster, more accurate order fulfillment

AI in warehouse automation can take end-to-end control of the fulfillment process, coordinating each stage: from picking, packing, sorting, and prioritization of stored or transported goods to their dispatch, all in real time.

An intelligent system can analyze the urgency of orders, assign shipments and auto-route pickers or other robotics and AI in warehouses accordingly. AI can recalibrate workflows on the go, based on fluctuating demand, warehouse congestion, or staffing availability. Lastly, it helps distribute tasks efficiently throughout the shifts.

Robotics and warehouse automation

AI can be set up to guide and calibrate robotics, like autonomous mobile robots, automated guided vehicles, smart assembly lines, etc. It enables them to take over repetitive, physically demanding tasks like transporting, staging, or palletizing goods.

It also boosts throughput and operational resilience, while freeing human workers from excessive manual work. In a truly harmonious human-robot collaboration, technology augments a live worker’s capability rather than replacing it, helping everybody fit where they are meant to.

Optimized workflows and route planning

In addition to sensitive monitoring and data collection that provides static layouts, AI offers dynamic insights and automation capabilities for enhanced workflows. For example, the AI-enabled workflow can adapt to order frequency, automatically launching the collection and sorting of goods based on aisle traffic.

With AI warehouse management, workers can predict aisle congestion before it occurs and reroute pickers or robots. This adaptability beats any pre-set plans, minimizes worker fatigue, and enables better space utilization by improvising task sequences and paths based on actual warehousing conditions.

Improved safety and workplace monitoring

AI can detect safety gear violations or hazardous behaviors, like missing personal protective equipment, working at an unsafe proximity to machinery, or unauthorized access to high-risk zones. An AI system will instantly generate alerts if immediate intervention is required.

A proactive hazard monitoring system that operates without downtime helps prevent accidents rather than simply backlogging them. AI can also predict future risks by analyzing patterns from previous near misses or zones where repeated accidents have happened.

Sustainability and cost efficiency

Using real-time sensors, AI-powered systems can smartly adjust lighting based on motion and natural light levels. They can also regulate temperatures based on occupancy or weather conditions. This responsive control dramatically cuts energy waste.

AI can also help improve how your warehouse space is used by analyzing traffic flows and picking patterns. Based on that, product slotting and storage configurations can be adjusted automatically, reducing travel distances and saving tons of energy in cooling and lighting.

Challenges of AI adoption in warehouse management

These are core barriers to consider when using AI for warehouse management that any company, entrepreneur, or startup should keep in mind.

Poor data quality

If any unstructured, incomplete, corrupted, or otherwise poor-quality data enters the AI/ML system, it must be immediately cleansed, completed, structured, or discarded. Otherwise, you will grow an unreliable AI model, whose decisions, predictions, and suggestions are twisted by clogged input data structures. This is why you need to feed your AI only clean, integrated data that comes from secure sources.

Legacy integration issues

For many running facilities, the use of AI in warehouse management is wholly or partially impossible due to legacy systems. There are outdated platforms that are very difficult to integrate with AI. These may call for either full re-platforming or partial refactoring of the entire infrastructure. Various WMS and firmware-based systems can still be used out of habit or due to their proven track record of years.

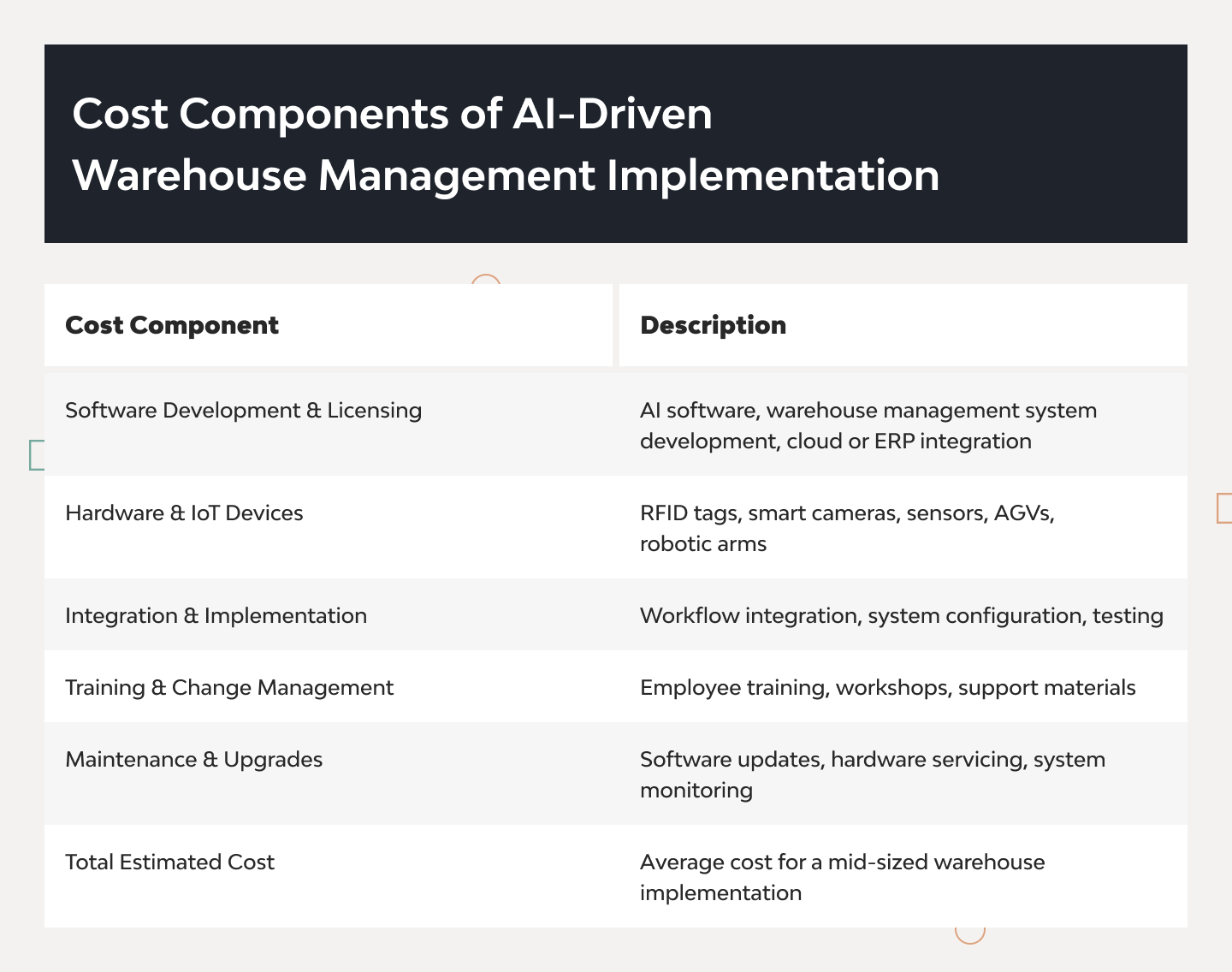

High upfront costs

Installing AI-driven robotics, sensors, or predictive platforms requires a significant investment dedicated solely to funding artificial intelligence warehouse management. You have to be ready and have a budget in place, an investor partner or two, or any other sort of financial backing. Warehouses are rarely startups, but the new AI equipment or funding for one can be earned with a good pitch and a long-term investor deal.

Shortage of technical expertise

The global adoption of smart tools is gradual, and skilled talent in AI and warehouse engineering is still in relatively short supply. If you can afford a good agency, there are market-proven tech partners for warehouse management system development. Otherwise, you may have to turn to outsourcing or custom onboarding for your existing staff.

How to implement AI in warehouse management

To implement AI for warehouse management, before all else, you should know what you need and what to expect from the new system, as well as which stages to prepare for. We can point out the five major steps that you should take to integrate AI in a warehouse.

Assess and pick use cases

Begin by conducting a comprehensive operational audit to pinpoint areas where AI can make a tangible impact — your inventory flow, fulfillment timelines, labor utilization, or system bottlenecks. Rank these potential use cases (e.g., automated picking, layout optimization, or predictive maintenance) based on their strategic value and feasibility. Run a small pilot to test the viability of AI in warehouse management. You can start with a focused pilot in one operational area to test effectiveness and measure results.

Prepare data

To give an AI high-quality, integrated data, you should clean and merge inputs from WMS, ERP, IoT devices, and sensor feeds. This data must be consistently shared and accessed across systems. Use this foundation to train machine learning models and boost the accuracy of their output of predictive analytics in warehouse operations.

Select the tech stack

Choose AI tools that fit your scale and goals, whether robotics-as-a-service, predictive modules, or vision systems. Consider specialized AI vendors and platforms for instant compatibility, ease of integration with your WMS/ERP, and warehouse-tuned technology.

Implement and onboard

Roll out new AI features in phases and create cross-functional teams (operations, IT, data science) to manage each stage. Train staff not just on the “what” but the “why” — show how AI supports their work rather than steals it. You can accumulate and use performance data and feedback loops to refine AI behavior.

Scale and optimize

After validating the pilot, you can start adapting a smart model to new product categories or demand patterns to expand the use of AI in warehouse management. You can track the AI’s performance against KPIs like pick accuracy, fulfillment time, and cost efficiencies. You can also retrain models using fresh operational data and integrate new capabilities.

Real-world use cases of AI in warehouse management

Some of the biggest brand storage facilities have been leveraging smart solutions across the board, backing up the tangible value of AI in warehouse automation. Here are some of them:

Optimized picking and slotting with robotics

Ocado utilizes mobile robots and robotic arms to pack around 40% of all orders now, aiming for 80% soon.

Zara reduced inventory errors to just 0.1% (versus traditional 3–5%) by automating item movement tracking through AI in warehouses.

Demand forecasting and inventory balancing

Unilever’s AI-on-weather custom platform improved ice cream sales forecasts by 10% in Sweden and 12% in the US.

Similarly, Walmart reduced stockouts by up to 30% through demand forecasting with artificial intelligence.

Predictive maintenance of equipment

DHL has been using sensor-powered AI warehouse management to anticipate mechanical issues, reducing downtime nationwide.

BMW utilizes AI-based visual inspection systems for detailed visualizations of any defects on its car body panels and components, employing high-resolution cameras.

Route optimization and warehouse layout planning

Amazon’s branded AMRs (over 750,000 in total) reduce walking distances by ~40%, while AGVs and simulations enable warehouse employees to visualize dynamic layouts of huge facilities.

UPS implemented AI in logistics of warehouse goods through the ORION system, which saved 100 million delivery miles and $400 million in transport costs.

Safety monitoring and sustainability

JD Logistics leveraged and deployed the AI vision systems to monitor safety gear, which allowed them to cut incident rates by about 30%.

Both DHL and Amazon, as well as FedEx, use the Protex AI solutions for safety and risk management in warehouses.

AI and warehouse management future trends

We can already see tangible, long-term benefits of implementing AI in warehouse management, including the adoption of smarter, automated, and centralized storage facilities.

- Spatial intelligence will enable robots to perceive depth and context in warehouses, prompting precision navigation and real-time AR overlays of warehouse environments.

- Humanoid robots are also on the rise, with early deployments by GXO and Agility Robotics testing AI-powered, human-like automation that will handle tasks at much higher efficiency, while being secure from human hazards.

- Comprehensive systems that are pre-optimized for artificial intelligence warehouse management are becoming the norm, prompting smart storage facilities with fully automated sorting that can be set up more cost-effectively.

Use of AI in Warehouse Management: Bottom Line

The use of AI in warehouse management gives facilities a competitive edge through robotics, automation, and analytics. Big-scale stockrooms of brand giants like Amazon and Walmart have already felt AI’s transformative benefits in the real world, with real consumers and market demands. However, the technology behind AI warehouse management is highly intricate and requires top expertise.

If you wish to follow suit and optimize your facility through AI automation, Django Stars will become your trusty warehouse management system development partner. We have qualifications and experience in integrating AI in warehouse management for operations of all scales. Contact us to discuss the end-to-end implementation of AI in warehouse management.

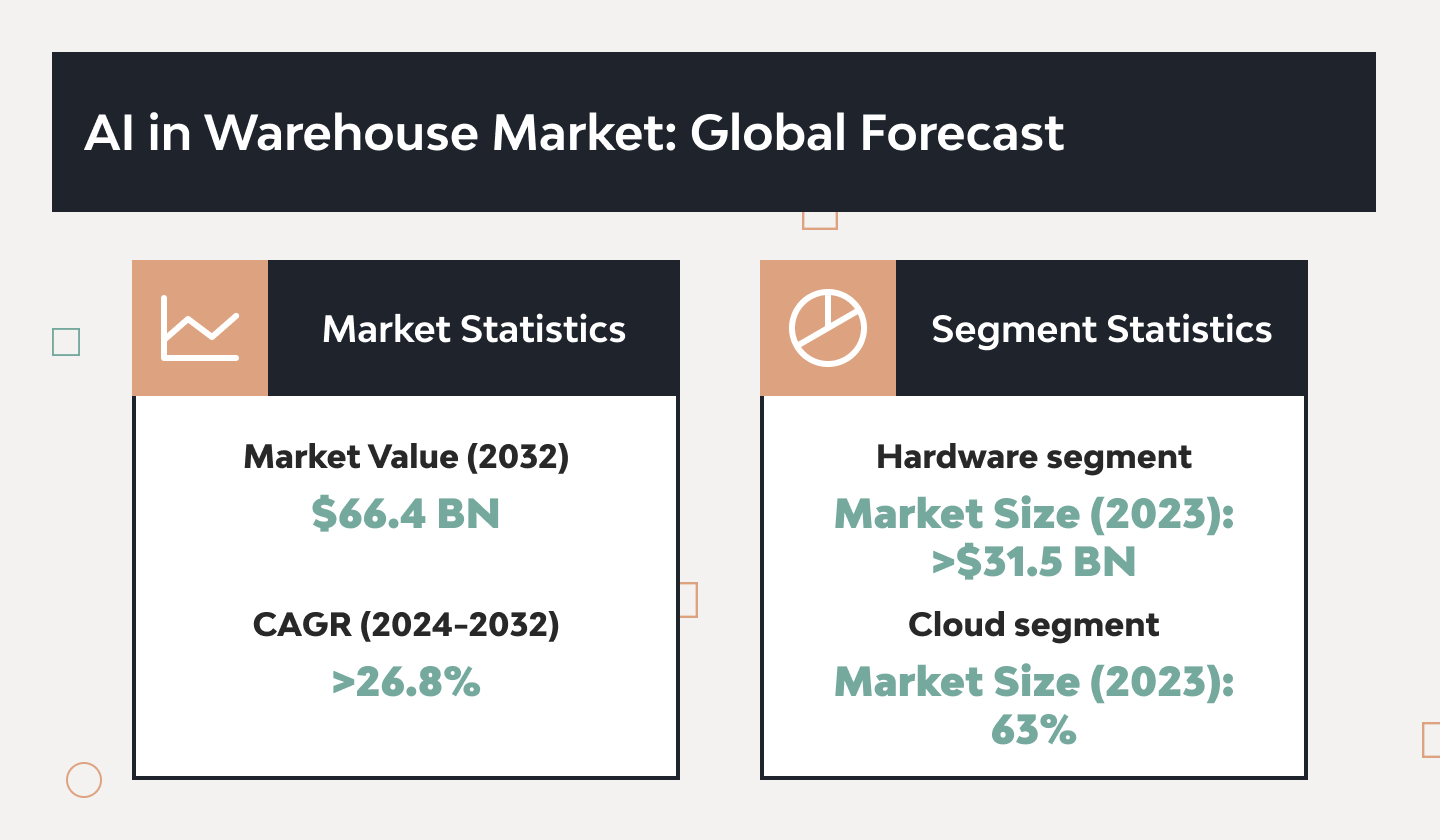

- How much does it cost to implement AI in warehouse management?

- The final cost may vary depending on the size of your facility, the scale of its operations, your technological ambitions, and your automation needs. There will also be different price ranges for more complex, all-in-one platforms and separate implementations, such as those focusing on machine learning for supply chain optimization or standalone AI modules.

- Is AI worth it for small and medium warehouses?

- Yes, all the mentioned benefits of AI in warehouse automation absolutely translate to smaller-scale facilities. You get to centralize the goods’ transportation logistics and other operations, optimize facility layout, and prolong equipment life through predictive maintenance. Furthermore, AI in warehouse management can be easily scaled as the brand expands.

- How long does it take to implement AI warehouse management solutions?

- You can start gaining real-time warehouse data insights and leveraging smart inventory management with AI in a couple of months. All you need is a reliable provider that will help you choose the technologies, set up an AI model, integrate the software, and provide tech support and maintenance. Once you team up with one, the implementation process may take from two to six months or more, depending on the warehouse scale and need for custom software.