3PL Providers: A Complete Guide to Effective Collaboration

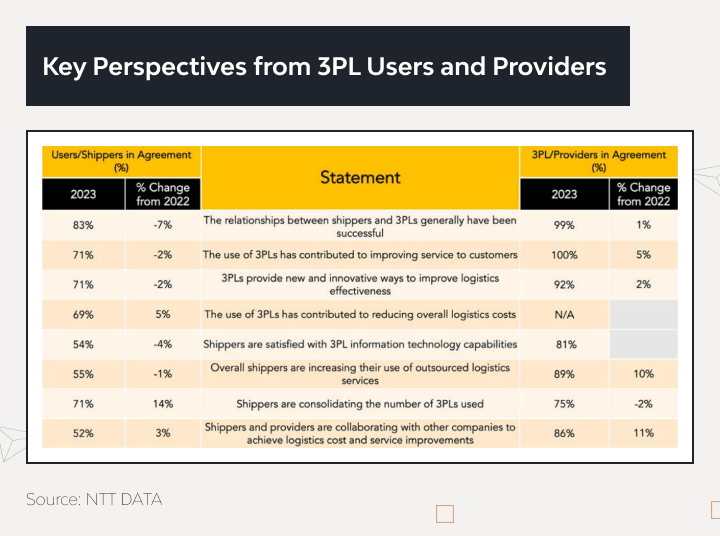

According to NTT Data’s Annual Third-Party Logistics Study, 56% of US shippers used third-party shipping management systems in 2022. The most prevalent activities shippers outsource are domestic transportation (67%), warehousing (63%), customs brokerage (46%), international transportation (44%), and freight forwarding (49%). What’s more intriguing is that 9 out of 10 shippers reported that their relationships with their 3PL providers have generally been successful.

As reported in recent years, shippers have greater expectations of what they need from logistics and supply chain service providers. While these organizations have responded with the best they can offer, it is apparent that overall issues with managing supply and demand, including capacity, have become overwhelmingly tricky in many instances. So, let’s explore how cooperation can benefit shippers and third-party logistics companies.

What is a 3PL Provider?

The abbreviation 3PL stands for third-party logistics. The name is quite clear since it describes logistics services rendered by one organization for another. The movement of cargoes performed by a 3PL company is exercised by leveraging a broad range of transportation means, such as motor vehicles (also known as over-the-road transportation), freight trains, airplanes, ships, or a balanced combination of these. Transportation methods employed by 3PL providers range from drayage and just-in-time models to specialized shipment of goods that require specific treatment (for instance, hazardous or perishable products).

The services offered by 3PL providers are categorized into distribution (warehousing, inventory management, and delivery), fulfillment (order processing, route planning, load optimization, kitting and assembly, drop shipping, last mile delivery, returns management, etc.), and transportation per se (brokerage, freight forwarding, dedicated cartage, and more).

The roster of services that 3PL firms provide depends on their type.

Types of 3PL Logistics Providers

When you are looking for a third-party logistics service provider, you are most likely to encounter one of the following types.

Transportation-Based 3PLs

You have surely heard of UPS, DHL, or FedEx? Well, these are the brightest examples of such companies, although there exists a slew of low-profile firms and local courier services in this niche. Whether you need to ship raw materials necessary for manufacturing a product or ready-made items to the consumer, they are here to do it for you. Additionally, they provide a range of related services, including distribution, transportation optimization, and last-mile delivery.

Warehouse/Distribution-Based 3PLs

Their primary focus consists of major warehousing operations (storage, inventory management, order fulfillment, reverse logistics, and more). They not only deliver an item from point A to point B, but also process the inventory, find it in the storage, assemble several products into a single parcel (if necessary), pack it in customer-branded wrapping, and deliver to the final destination, enabling the customer to track the process in real-time. As ancillary services, such companies provide returns handling. They receive the returned items at their facilities to be restocked, refurbished, or disposed of down the line.

Forwarder-Based 3PLs

They serve as a go-between in delivering the client’s cargo to transportation-based 3PL providers. On the one hand, they perform consulting services, advising individuals and enterprises on the shipping options, routes, processes, and delivery models available to them. On the other hand, such companies negotiate prices, optimize transportation modes, and manage all shipment details by communicating with delivery organizations. All transportation-related concerns, even customs clearance, are their province.

Full-Service 3PLs

Thanks to their own transportation management platforms and tools, these outsourcers exercise end-to-end logistics management services. Customers can pick whatever function they need from the roster (whether it is accounting, claims management, or logistics reporting and analytics), and the full-service 3PL company will cover it. If you delegate the entire logistics pipeline to such an organization, you can focus on your core activities and forget about all logistics-related headaches.

Financial-Based 3PLs

They are well-versed in the financial implications of logistics processes. Such enterprises employ finance and accounting personnel responsible for cost accounting, freight payments, conducting audits to identify late deliveries, errors, and incorrect charges, handling contract negotiations, optimizing rates and terms, collecting claims payments, and other related tasks. Thanks to them, organizations can streamline and facilitate all financial workflows, unlocking savings opportunities.

Information Technology-Based 3PLs

These are, in fact, 3PL solutions functioning as networks of logistics services or even all-in-one marketplaces. There, businesses and individuals can find quotes, read customer reviews, broker freight delivery, and fulfill all their transportation needs. Some of the IT-based 3PLs even expand into the ride-sharing market, arranging relationships between drivers and delivery organizations.

By selecting the right type of 3PL company, you can reap numerous business benefits.

Benefits of Partnering with 3PL Providers

During 27 years of cooperating with organizations across various verticals, Django Stars has witnessed many of them encounter problems not because the products they manufactured or sold were of low quality, but because enterprises failed to deliver them effectively to end users. What are the benefits of companies using a 3PL model that allow them to address logistics challenges they face?

Cost Savings

3PL providers have a much more comprehensive logistics network than most manufacturing and retail companies. Moreover, they have numerous agreements and relationships with contractors, which enable them to propose more competitive delivery prices and minimize overhead costs.

Connecting shippers and third-party logistics providers also reduces investments in shippers’ infrastructure, such as warehousing, route analysis and optimization, delivery tracking, and staff training.

Scalability and Flexibility

A large 3PL company will offer businesses almost infinite supply chain scalability that covers even the most ambitious business needs. If things go up, managers don’t need to worry about logistics – 3PL systems will cover all demands. However, during tough times, businesses simply pay less for goods delivery.

Expertise and Advanced Technology

For a manufacturing company, providing the level of logistics expertise required for all regional markets can be quite challenging, especially when operating in different countries. Shipment of goods may have different rules regarding documentation processing, import and export prohibitions and restrictions, economic regulations, and other conditions and features. Besides, a 3PL company usually employs cutting-edge solutions and innovative technologies to streamline and facilitate all shop floor operations. Moreover, connecting shippers and 3PL providers helps businesses expand into international markets without delays and a smoother entry into new regions.

Focus on Core Competencies

As a rule, organizations competent in their sphere of interest often lack qualified staff to handle the logistics pipeline effectively. Cooperating with a 3PL company enables businesses to focus on their core competencies instead of struggling with resource-intensive activities and training their personnel to handle them. Companies can utilize the extensive logistics expertise of 3PL providers without having to deploy their own internal resources.

Improved Customer Service

While you learn to handle shipments effectively, you can’t entirely avoid mistakes and inefficiencies, which may deter consumers who expect the best service for their money. Proper shipping management software, leveraged by high-end 3PL providers, dramatically improves the quality of customer service and reduces the number of delayed deliveries to almost zero. This, in turn, leads to more satisfied consumers and enhanced brand loyalty — precisely what businesses need.

Risk Mitigation

Improved visibility and forecasting, ensured by data-driven analytics, adaptability to market fluctuations, reliance on top-notch expertise, adherence to quality control measures, and utilization of a diversified transportation network provided by 3PL companies dramatically reduce risks and incidents associated with transportation workflows.

Streamlined Operations

This advantage is ensured by the disruptive solutions 3PL companies utilize in their routine. Thanks to them, third-party logistics enterprises can exercise real-time tracking of all delivery processes, simplify such complex workflows as international shipping, reverse logistics, or handling returns, improve warehousing and inventory management, maintain efficient supply chains, optimize routes, and enhance other pipeline activities associated with transportation.

Alongside unquestionable benefits, delegating logistics to 3PL organizations incurs some roadblocks and bottlenecks.

Key Challenges and Considerations When Working with 3PLs

The past few years have been challenging for shippers and third-party logistics companies. The post-pandemic market remains unstable and transformative, resulting in various capacity issues for supply chain logistics services and fluctuating market demands. The process of connecting shippers and third-party logistics service providers is undergoing constant transformation, revealing a series of issues. Let’s take a closer look at them.

Loss of Control and Visibility

Outsourcing any function inevitably involves a loss of control, and delegating transportation duties to a 3PL logistics company is no exception. Businesses that hire 3PL organizations can’t hope to constantly keep their finger on the pulse of every delivery or oversee each item handling. Yet, by outsourcing workflows, you never outsource responsibilities for the outcome. That is why, instead of managing tasks, you should learn to manage results. Adequate governance and oversight, coupled with regular performance reviews, will ensure that all service and quality standards are consistently met.

Communication Issues

Since businesses typically hire 3PL providers from their own country and region, problems such as language barriers, cultural differences, or time zone discrepancies, which are common in offshore cooperation, are generally irrelevant here. However, it doesn’t mean that communication between parties is always smooth. To establish a mutual understanding, establish clear communication protocols, leverage effective interaction channels that are comfortable for both parties, and foster a trusting relationship as the foundation for fruitful cooperation.

Quality and Service Standards

Nothing is perfect in this world, and even the best 3PL provider may occasionally experience performance issues or accidents (for instance, delivery failures or delays, transportation disruptions, cyberattacks, etc.). To minimize the impact of such problems on your company’s performance and customer satisfaction, you should set up and negotiate KPIs with your partner and ensure their continuous monitoring. It will help you spot problems as soon as they arise and address them promptly.

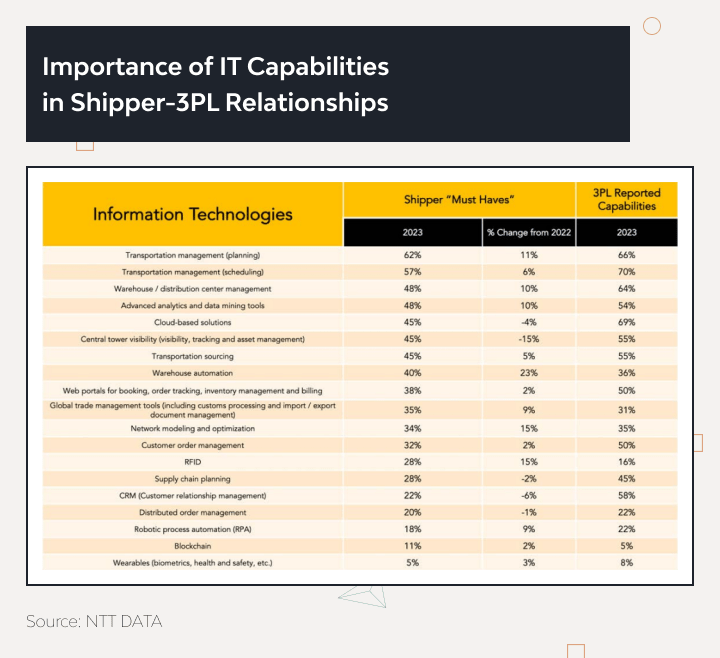

Technology Integration

This problem arises each time when two parties poised for cooperation use disparate data formats, protocols, and structures, or employ different cloud providers. If it happens, errors, duplications, and other issues can hinder seamless tracking, transparency, and operational efficiency, resulting in a lower level of service and a substandard customer experience. So, when you hire a 3PL provider, don’t forget to standardize the aspects mentioned above from the outset.

Managing Demand Fluctuations

The logistics realm is an extremely volatile domain where demand and supply often fluctuate, requiring both 3PL companies and their clients to quickly adapt to new market conditions. The two most effective ways to stay informed about all shifts are to enable broad-scale process automation and leverage robust logistics real-time analytics, and forecasting solutions. Such measures enable logistics experts to monitor transformations in real-time and detect patterns in both historical and current data. As a result, they can promptly introduce changes to route planning, implement flexible inventory management practices, and dynamically adjust other shop floor operations to match supply with demand.

Hidden Costs

These stem from customers’ failure to understand all the contract details concerning the pricing structures that 3PL companies offer. As a result, they have to defray out-of-pocket expenses for services they thought were included in the packet but in fact weren’t.

The responsibility for avoiding such awkward situations rests with both parties, as they should take mutual steps to build partner trust. Businesses hiring 3PL providers should carefully review the agreement to ensure they understand what they are paying for and what they aren’t. Third-party logistics organizations should clearly define the scope of their services and explicitly outline roles and responsibilities in the documents they sign with customers.

Recognizing and addressing these challenges successfully are mission-critical aspects that ensure smooth cooperation with a 3PL provider. Yet before that, you should select the right company to partner with.

How to Choose a 3PL Provider: An Algorithm to Follow

The current market in this sector is filled with dozens, if not hundreds, of organizations offering their transportation services. How to choose a 3PL provider logistics partner for lasting and reliable cooperation? Here is a roadmap for you to stick to.

Assess Your Business Needs

Your requirements largely condition the choice of a partner with a respective roster of 3PL services. So, what do you need? Is it just transporting items to the destination, or could you use some last-mile delivery services? What about storage and kitting assembly? Do you need help with returns management? Will your in-house staff tackle accounting, or is external assistance necessary? Is your business international and faces customs issues that you would like to delegate? When you have answers to all these questions, you know the specific criteria for selecting the future partner.

Research Potential Providers

Having all your requirements as a yardstick, sift through the candidates and make a shortlist of 3PL companies that suit you. Then, study each candidate on the list, paying close attention to customer reviews, niche ranking platforms (like Gartner), and referrals from trusted sources. Don’t be shy to contact organizations and individuals who have left their testimonials on the provider’s site and discover their opinions regarding various aspects of cooperation that weren’t mentioned or published.

Check for Experience and Expertise

These vital aspects can also be learnt from the information on the potential partner’s site. Look for the industries the provider specializes in, network size (especially in the region of your interest), the company’s capabilities to deal with different cargoes (fragile, precious, oversized, hazardous, etc.), and proven indices showcasing the organization’s effectiveness in route optimization, risk management, cost reduction, meeting deadlines, and complying with regulations. The portfolio section of the site is the primary source of such information.

Evaluate Technology and Integration

In the modern IT-driven world, technology serves as both a competitive differentiator and a performance facilitator. 3PL companies that fail to realize this truth can’t hope to address challenges symptomatic of the logistics industry today. Suppose the potential candidate on your list leverages a custom-built ERP inventory management platform, implements innovative React Native location tracking, and utilizes state-of-the-art 3PL solutions for AI-fueled data analysis. In that case, it is a telltale sign that the firm is staying current with the latest technological trends in the domain.

Also, make sure the company’s digital infrastructure is flexible enough to integrate with your own IT environment, particularly in terms of data formats.

Understand the Pricing Model

These are often quite confusing and contain additional fees for specific conditions or certain services (like customized reporting and analytics). To avoid unpleasant surprises and potential conflicts, it is advisable to inquire about pricing before committing. The points of interest encompass services included in the quote, payment structure (flat fee, hourly rates, per item, per order, or other), hourly charges for activities (typically, these include cycle counting or kitting), processing charges for picking and packing, and possible hidden fees (postage, import fees, etc.).

Review Scalability and Long-Term Partnership

Every business with big-time aspirations has far-reaching growth plans. Yet, they may fail if logistics considerations aren’t taken into account. That is why, when starting a partnership with a 3PL provider, you should make sure it has the potential to scale up its operations. It is also important that upscaling capabilities cover seasonal spikes and shifts in demand, as stipulated by the contract.

If you are satisfied with the initial stages of cooperation, it is recommended to develop a long-term partnership with the 3PL company you work with. Then, you will be able to save a pretty penny by signing a multi-year agreement. Just make sure it addresses the annual cost escalations characteristic of the field.

Come to a Decision

When you finally opt for a 3PL provider, it is wise to embrace a multifaceted approach. Certainly, the cost issue is crucial, but pursuing the lowest price may ultimately prove to be a flawed strategy. Consider all aspects from a comprehensive perspective and select a business partner rather than a service provider.

That said, a clearly defined service level agreement (SLA) remains the bedrock of your cooperation. Ensure it includes all essential performance metrics, terms, and conditions.

The successful cooperation between a customer and a 3PL company hinges on the effective interaction and communication channels they rely on.

Connectivity Types between Shippers and 3PL Providers

Nowadays, there are three main ways to establish a secure and stable connection between a manufacturing or retailing company and a 3PL provider:

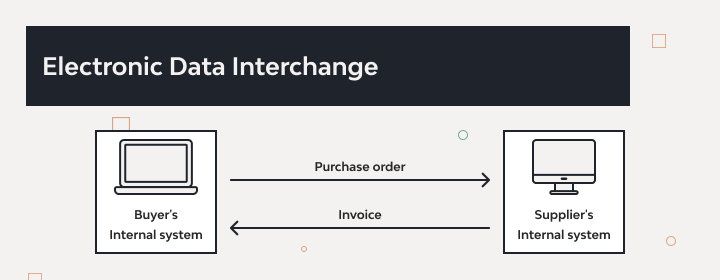

- Electronic Data Interchange (EDI). Exchanging messages is a relatively old but still widely used method of sharing data between shippers and third-party logistics (3PL) companies. Partners send each other encrypted messages with all the required data, which is then manually processed by managers. However, keeping EDI safe and preventing data leaks requires long-term staff training, which may be pricey. Nevertheless, it remains convenient for small businesses, but it can’t be recommended for mid-sized or large companies with dozens of supply chains processed simultaneously.

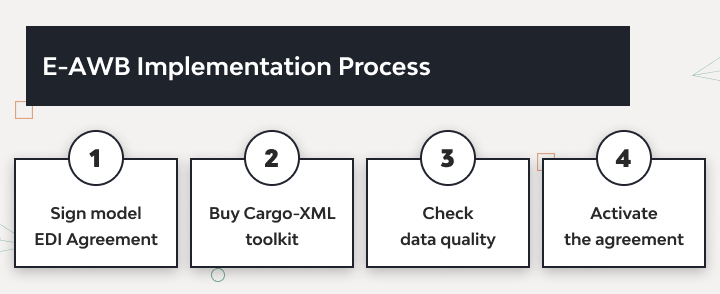

- Electronic Air Waybill (e-AWB). It’s the next level of EDI communication, designed initially as a message-exchanging method for airlines. However, e-AWB unifies document formats, making bookkeeping much easier, but it simultaneously requires human resources. Large businesses may also use this method. For example, Hellmann Worldwide Logistics, an international logistics company, sends and receives over a thousand shipping documents monthly via e-AWB, operating efficiently.

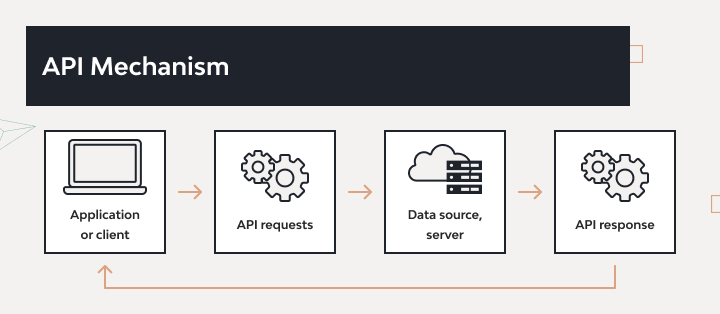

- API Third-Party Logistics Systems. This method directly connects the digital applications of a shipper and a 3PL company that automatically sends, receives, saves, and processes all required data in specified formats. For example, if a manager seeks data about a specific delivery, they don’t need to contact anyone. They need to create a particular request in the application. If such data exists and is allowed to be shared, the manager gets it almost immediately.

API works as a translator between different applications, servers, and interfaces. It requires a substantial amount of resources to set it up correctly, but very few to operate.

The most used API are REST (Representational State Transfer) and SOAP (Simple Object Access Protocol). REST is more prevalent in supply chain management because it works flawlessly with all required file formats, including XML, HTML, TXT, and JSON.

Conclusions

Modern manufacturing and commercial organizations often don’t have their own in-house transportation facilities to store and deliver their products to consumers. If this is your case, you can outsource such tasks to a 3PL logistics company. In addition to their core services, these enterprises offer a range of capabilities, including accounting, warehousing, last-mile delivery, drop shipping, kitting and assembly, brokerage, and other services. Their efficiency is increased manifold if they leverage top-notch solutions in their shop floor operations.

Experienced logistics software developers can significantly enhance the supply chains of manufacturing and retail brands, ultimately increasing customer loyalty and satisfaction. It’s acceptable as both an urgent solution and a strategic partnership.

- What services do 3PL providers offer?

Full-service 3PL provider offers an entire scope of logistics services.

They include:

- transportation

- warehousing

- inventory management

- order processing

- accounting

- kitting and assembly

- last mile delivery

- returns and claims management

- freight forwarding

- dedicated cartage

You name it.

- What is the difference between 3PL, 4PL, and 5PL?

- 3PL providers focus on the basic logistics operations like transportation and warehousing. 4 PL enterprises specialize in comprehensive supply chain management for their clients. 5 PL providers go further than that and create intelligent, automated, AI-based solutions aimed at full-cycle optimization of supply chain and delivery operations.

- How long does it take to onboard a 3PL provider?

- Basic transportation operations can be set up within two weeks, whereas complex workflows with custom packaging, warehousing, and technology integrations typically take several months to launch.