How to Build Inventory Management Software: Step-by-Step Process

Innovative inventory management is a critical business process that influences the efficiency of supply chains at every juncture. Mistakes in this area can lead to significant issues, including errors during shipping, product shortages, miscommunication with customers, and an elevated risk of theft.

Even more concerning is that inaccurate inventory data can drive misguided business decisions, the consequences of which can be far graver than even extended shipping routes or delivery delays. This underscores how imperative inventory management software solutions can be for e-commerce companies.

According to a review by Statista, over 40% of logistics companies leverage inventory optimization tools to enhance the efficiency and cost-effectiveness of their supply chains, especially when experiencing rapid growth.

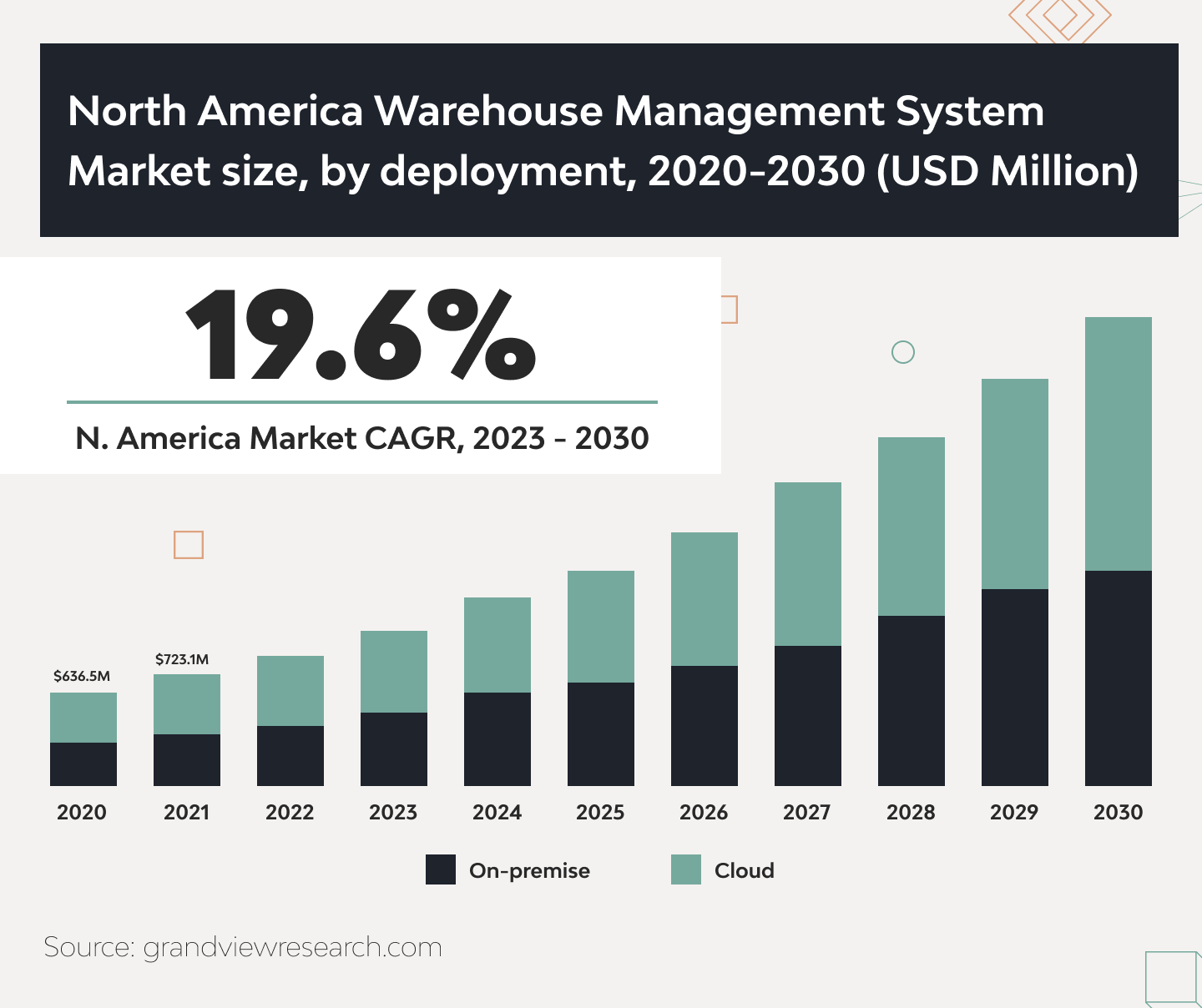

The North American market for IMS is on an upward trajectory, growing at a CAGR of 19.6%. Within this market, the logistics segment is expanding the quickest, with a forecasted CAGR of 20.2% from 2023 to 2030.

In 2022, European countries dominated the IMS market, accounting for 31.49% of global revenue. The Asia-Pacific region is demonstrating remarkable growth in the industry, particularly in China and India.

On the American continent, the USA stands as the undisputed leader in both providing and developing inventory management software solutions.

What is inventory management software?

IMS, for short, is a digital system, platform, or collection of tools designed to track, organize, and optimize the management of goods throughout their lifecycle. The IMS syncs up the processes from purchase and storage to movement and sale. It also replaces manual spreadsheets or paper logs with a centralized database that autonomously records stock levels, goods’ location, batch numbers, and item movements.

As with any other digital solution, there are off-the-shelf IMS platforms and custom inventory management software solutions. Ready-made tools can be deployed quickly for an immediate start with standard features. In turn, going for bespoke inventory management software development, a business can build the IMS around its unique workflows, implementing just the logic and features it needs.

Types of inventory management software

While serving similar or even identical purposes (i.e., tracking the storage, registering goods, and automating processes), an inventory management software system can take on many shapes and sizes. But the most common formats include the following ones.

Perpetual inventory systems

A perpetual system tracks stock levels at all times and updates the inventory ledger each time an item is received, sold, or moved. This is registered via barcode scanners, RFID tags, or integrated software, which show up-to-the-minute stock levels. Managers can use this to trigger reorder alerts and avoid stockouts.

Periodic inventory systems

In a periodic inventory management software system, inventory and cost of goods sold (COGS) are updated only at scheduled intervals — weekly, monthly, or annually. The seeming downside is that between inventory counts, the physical stock may change while unlogged in the system and the IMS data lags. However, it works for smaller businesses without high uptime.

Just-in-time (JIT) inventory systems

Usually a product of custom inventory management software development, just-in-time systems are individually tuned to keep inventory at minimal levels. They trigger the order of goods or raw materials only as needed, based on the production or sales demand. This helps cut holding costs and waste, but also requires reliable suppliers and on-site control.

FIFO and LIFO inventory systems

Inventory systems are also designed based on two alternate product valuation and flow methods: First-In, First-Out and Last-in, First-Out. FIFO assumes the oldest units are sold first. LIFO assumes the newest items are sold first. At the core of IMS, these methods help shape how cost and ending inventory are reported under either periodic or perpetual systems.

Hybrid systems

Tailored inventory management software development allows creating hybrid solutions that blend two or more methodologies. Your new IMS may combine periodic and perpetual tracking, JIT with safety stock, or push and pull models. This way, you can tailor inventory control to varied products or demand profiles, achieving flexibility and balance between cost-efficiency and responsiveness.

How does inventory management software work?

By creating an inventory system, a business can leverage proven functionalities.

Tracking and monitoring

Above all, IMS enables unified tracking and monitoring of every stock item. It logs when new stock arrives, when items move between locations, and when they are sold. Using barcodes, tags, or IoT sensors, the system records and updates item status — you always know where a unit is, what condition it’s in, and if it’s available.

Real-time updates

Today’s inventory management software systems sync all inventory changes instantly, once a sale is made online, a shipment arrives at the warehouse, or stock is transferred. The real-time flow of updates prevents overselling and stockouts, and keeps all departments working from the same up-to-date data.

Automation

The IMS system can launch reorder submissions when stock falls below thresholds and generate purchase orders. It can allocate items according to fulfilment tasks, and suggest optimal re-locations. Autonomous workflows reduce manual work, speed up response, and free staff to focus on higher-value tasks.

Demand forecasting

Using historical sales data, seasonal patterns, and stock levels, IMS can predict what goods you will need the most, when you will need them, and where. AI algorithms and predictive analytics enable forecasting that helps you stock enough goods to avoid shortages yet not over-invest in excess.

Centralized data

Inventory management software development allows you to bring all stock-related information into one unified platform. The data on product location, supplier, sales channels, and other details are all available in one place. And custom visualizations make it accessible for teams across warehouses, stores, and online shops.

Core features of inventory management software

Inventory management software systems are complex tools with many separate features — here are the main ones:

Real-time tracking

IMS helps track and sync data about product cost, availability, SKUs, expiry dates, locations, alternatives, etc., keeping warehouse teams and clients in check.

Automated reporting

Logistics and delivery reports can be generated automatically, providing statistics for warehouse management teams and important order estimations for clients.

Low inventory alerts

One of the life-saving inventory management software features is the stockout prevention — IMS tracks the available goods and alerts managers to timely refill them.

Multi-location management

The location-tailored IMS allows managers to monitor the amount of goods stored in different warehouses and calculate their delivery in relevant conditions.

Integration capabilities

With so many available add-ons, your inventory management software development shouldn’t be isolated — you can integrate with ERP, POS, and CRM systems.

Barcode/QR code scanning

IMS solutions are normally equipped to read and analyze product codes, sensors, and tags, helping to visualize an entire range of warehoused goods and their metrics in one place.

Order management

Logistics managers and clients may quickly find out the exact location of an order and its estimated arrival time thanks to all the above features synced up into a single UX pipeline.

Benefits of using inventory management software

IMS is a proven tool to boost the speed and reliability of warehouse management, inventory, and logistics tasks and processes. Here are the main advantages of inventory management software.

Increased efficiency

Implementing an effective IMS can reduce the time and effort required to deliver products. A manager doesn’t have to check all data manually. With a few clicks, he/she would know everything they need about shipping routes and the number of goods available, even for a complicated request.

Reduced costs

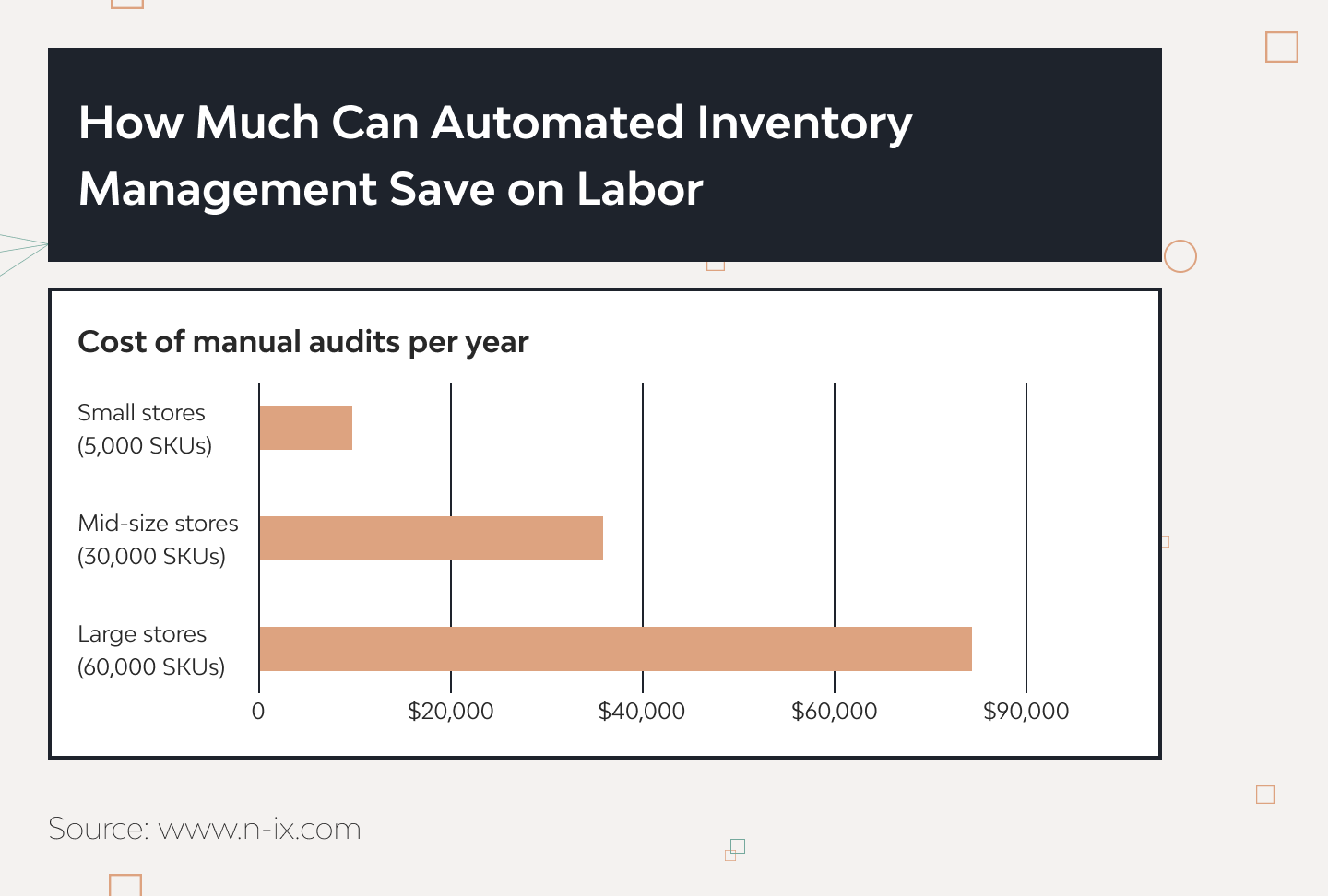

Delivery processes can be optimized inside-out by analyzing clients’ demands and shipping patterns. With an individually tuned inventory management software design, a logistics company may lower the delivery prime cost through routine automation, insightful tasking, and workflow optimization.

Improved accuracy

Building an inventory management system is an effective way to eliminate manual logistics processes with a high risk of human error, which may lead to financial and reputational losses. Using inventory management systems thus prevents basic calculation, updation, and notification mistakes.

Enhanced decision-making

An IMS system equipped with AI and ML algorithms can help analyze seasonal trends and forecast demands. With tailored inventory management development, you can integrate analytical tools to track market demands for particular goods and plan delivery processes more accurately.

Better customer satisfaction

A client gets complete information about delivery times and methods, order frequency, packing, billing, and conditions of carriage. If something goes wrong, this will be made known immediately. So, a logistics company will have enough time to diversify the shipping process.

How to build inventory management software

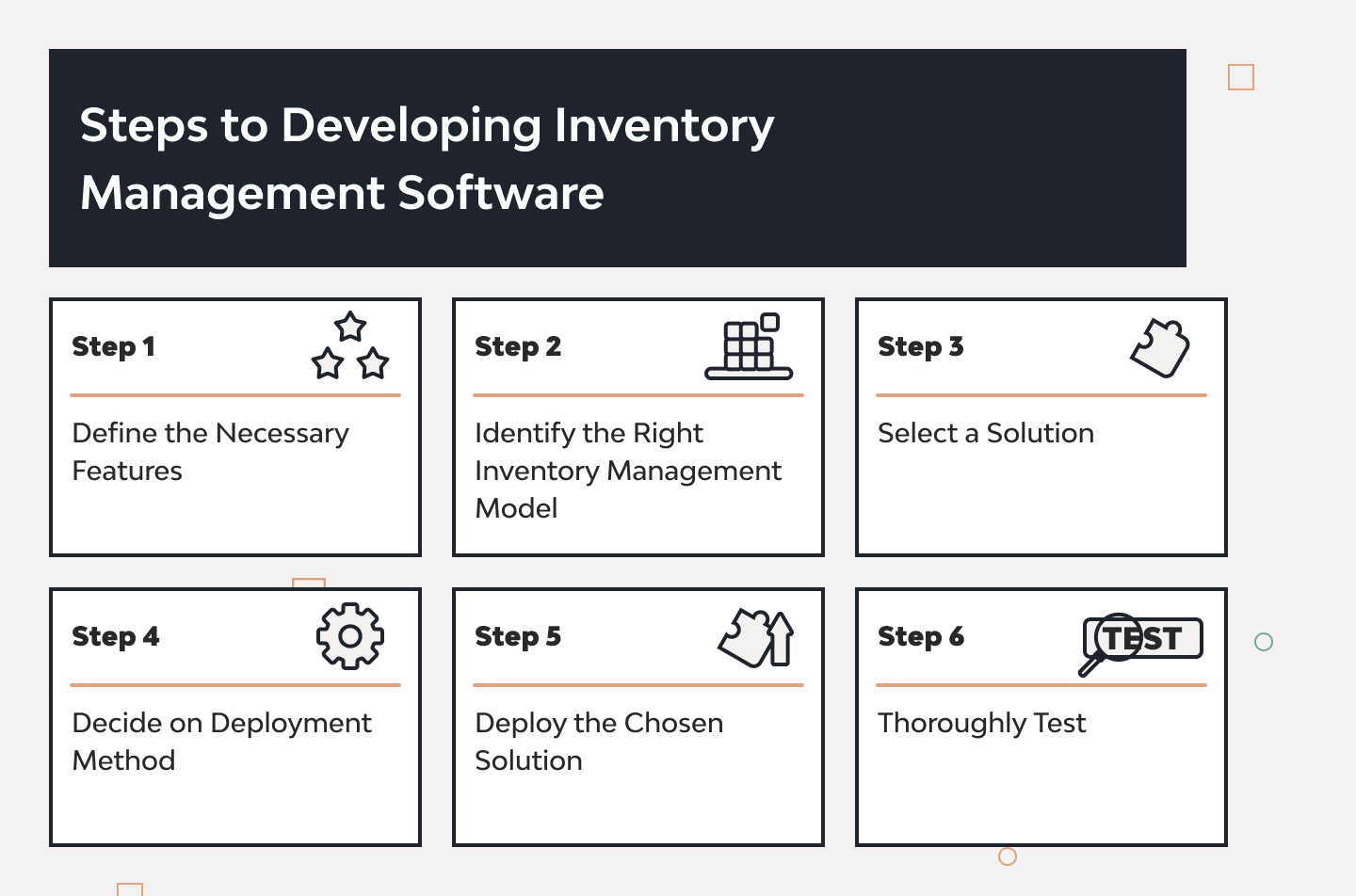

From theory to practice, here’s how to set up an inventory system in several common stages:

Requirement gathering

Conducting stakeholder interviews, defining scope, and setting success criteria. Documenting pain-points, functional and non-functional requirements.

System planning and architecture

Selecting the tech stack, creating high-level diagrams, and wireframing the software architecture, including modules, data flows, database schema, and integration points.

UI/UX design

Laying out the inventory management software design, crafting user interface interactions, outlining user flows, and working through the usability of the overall user experience.

Development and QA

Creating an inventory system core, writing code modules for the main functionalities, and executing unit and system testing scenarios to verify the software’s eligibility.

Integrations with third-party systems

Building inventory management system expansions, connecting third-party ERP, WMS, TMS, or POS platforms, mapping data flows, and setting up authentication and user rights.

Data migration

Extracting stock data from legacy systems or spreadsheets, cleansing and transforming the data to match new schema, loading assets into a new system, and running pilot test loads.

Deployment

Configuring servers, cloud setups, and security backups, deploying the infrastructure and loading the application, running final smoke tests, and monitoring post-launch performance.

Training and support

Providing guidelines and onboarding for new users, establishing support channels, collecting mid-performance feedback, and maintaining software via patches and fixes.

How much does it cost to develop inventory management software?

Looking at all its workflow-boosting benefits, the main question arises — how much does building an inventory management system actually cost? To give you the best approximate figures, here are the commonly estimated budgets you should expect for different approaches to inventory management software development:

Basic IMS (MVP)

Startups or small businesses that only require the core IMS functionality (e.g., stock tracking, alerts, and basic reporting) can start with a cost-saving Minimum Viable Product. It can be easily built for a single warehouse, with minimal integrations.

An MVP should take roughly 3–6 months to complete, with a simple UI/UX and some customization. The estimated cost of such IMS would range USD $20,000–$50,000.

Mid-level IMS

For growing companies with multiple locations or warehouses, need for multi-site tracking, mobile scanning, and more detailed analytics, the development timeline can stretch to 6–9 months or more.

Added features, more complex UI/UX, data migration, and multiple user roles grow the price approximately up to the USD $40,000–$120,000 range.

Enterprise-grade solutions

Large-scale, multi-warehouse, global operations that require IoT sensors or RFID tags, AI analytics, multi-tenant cloud, and complex integrations are looking at a higher overhead investment.

For custom inventory management software, the development timeline may be 9–13+ months. The entry point for such software would be at USD $100K+.

3 best inventory management software examples

Ready-made inventory management systems suit eight of ten e-commerce companies, even the international ones.

Django Stars’s experts have already analyzed the IMS market, including data available on Capterra, G2, and Trustpilot, and picked three of the most convenient and valuable solutions for a logistics company:

Katana

Forbes Advisor rating: 4.8 of 5.

Pricing: from $99 to $599 monthly.

Katana is a full-scale system for order tracking, inventory management, and delivery route monitoring. It has many features useful for e-commerce or B2B business: goods manufacturing, warehousing, and logistics.

Pros:

- Reasonable pricing.

- Highly customizable solutions.

- Time-saving tracking features.

- Free 14-day trial.

Cons:

- It may be expensive for international business.

- No phone support.

Ordoro

Forbes Advisor rating: 4.9 of 5.

Pricing: from $59 to $149 monthly.

Ordoro is a complex solution that includes supply chain management, multichannel sales, warehouse management, and shipping. Each Ordoro feature may be integrated with most e-commerce stores and online marketplaces.

The system is highly automated: it can even forward orders from several warehouses and find the best routes with a few clicks. Ordoro provides convenient features to analyze and forecast the shipping process and has an extensive online knowledge base.

Pros:

- Top-level service integration with other e-commerce and marketplace systems.

- Automated warehouse and shipping management

- Built-in features for analysis and forecasting.

Cons:

- Full-scale solutions are pricey.

- No mobile app.

Cin7

Forbes Advisor rating: 5 of 5.

Pricing: from $325 monthly.

Cin7 is a top-notch management tool for all aspects of e-commerce: inventory tracking, warehouse monitoring, and shipping management. It’s highly customizable and flexible so that it may be used as well as a single-point solution or an infinitely scalable turn-key e-commerce system.

It’s especially recommended for ambitious sellers and logistics companies who want to automate all internal business processes.

Pros:

- It may be integrated with the most significant marketplaces and shipping platforms.

- High level of automation.

- Unlimited scalability and flexibility.

Cons:

- It’s pricey, especially when adding users.

- There is only chat client support.

Forbes Advisor created its rating for the top inventory management software. There, you can find the best systems for small and big manufacturers, sellers and logistics companies, point or full-fledged services, and even very niche solutions. Read it to learn more.

How to choose the right development partner

Here is the step-by-step guide about how to find a solid and well-coordinated team to delegate all the work with IMS.

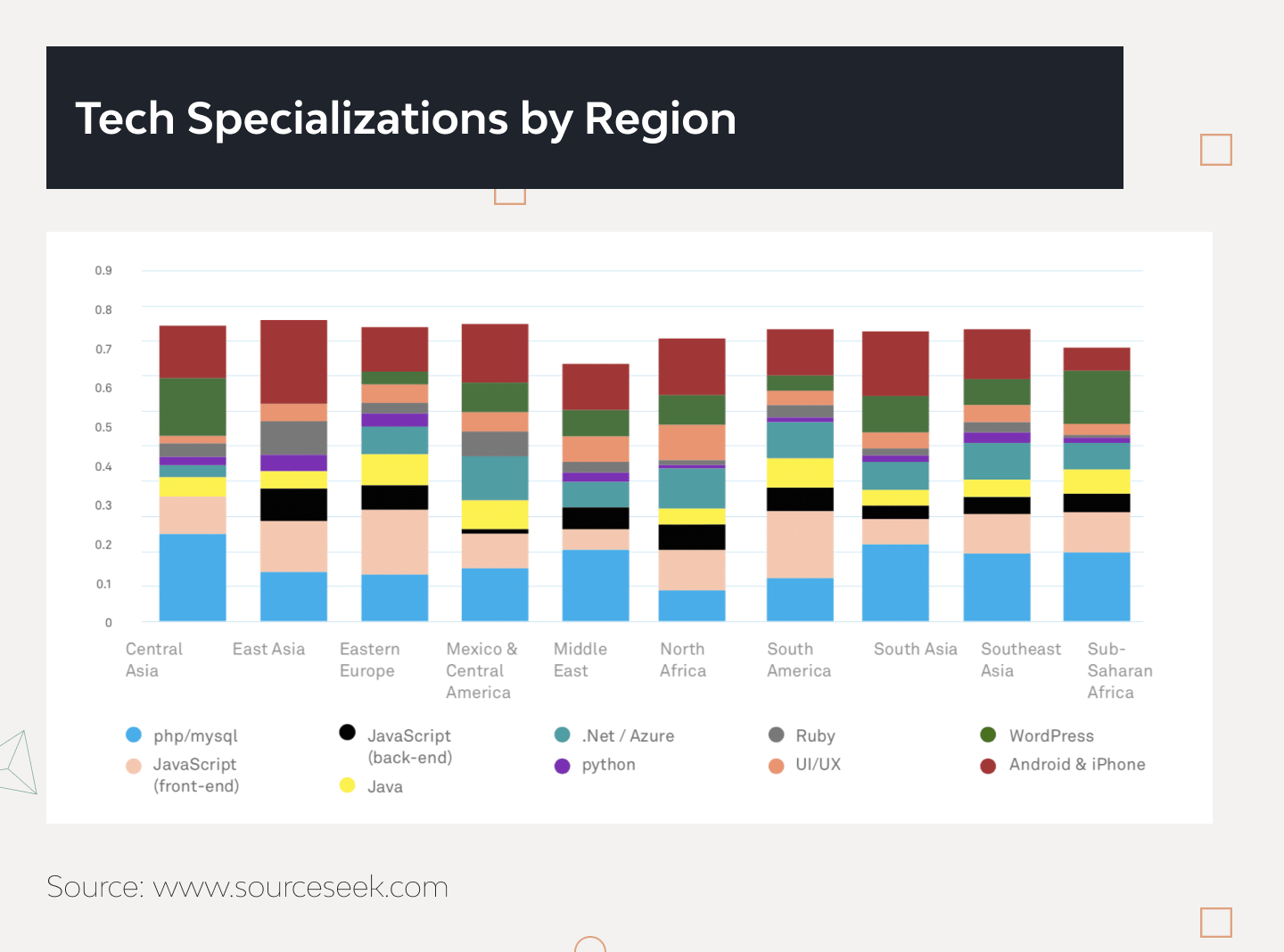

Explore dedicated, outsourced, and augmented teams

Kicking off the development and deploying the inventory solution is fine, but first, you must choose the team. We recommend picking the best-fitting collaboration model. You can also leverage experts from abroad.

In the chart below, we have the data about development technologies popular in every region.

The more technologies used in your chosen solution are there, the more likely you are to find a team that can help you in ISM development.

Sometimes, hiring a team with solid experience in required technologies is better, even if they are far abroad.

Evaluate the technical expertise of the provider

Analyze your company’s goals and the technologies in their stack. For example, Django Stars uses Python as our primary programming language and has deep expertise across every aspect of product development with its frameworks and tools.

On top of that, we have lots of successful solutions designed in different areas of business: booking, video streaming platforms, logistics software development services, CRM and ERP systems, and high-load applications. We also help clients navigate modern integration challenges such as EDI vs API.

We have all the required skills and knowledge to design and develop any inventory management solution you need, from small-point solutions for solving a single specific task to full-fledged systems for an international e-commerce company.

Choose a contractor with a decent portfolio

Looking through successful IT product development is the best way to check a prospective vendor. Also, we recommend starting cooperation with the discovery phase and discussing the concept of the ecosystem you require.

Inventory management software can be used as a standalone solution for solving a specific task in logistics or as a part of a full-fledged ecosystem, including everything you need to lead any e-commerce business.

- How can an inventory management system help an e-commerce business?

- IMS is designed to solve business tasks related to goods storage, warehouse management, and delivery optimization. When the data is collected correctly, the system prevents human mistakes when choosing routes and optimizes the delivery process. It’s a handy tool for improving logistics on the financial and reputational sides.

- Is inventory management software suitable for small businesses or only large enterprises?

- IMS solutions are suitable for both small companies and international holdings. Most of them are flexible and scalable, so they can solve small logistics tasks and control the entire process performance of an e-commerce company.

- How secure is the data stored in inventory management software?

- Providers of IMS solutions use data encryption and protected data centers to ensure safe data storage and operation. On the technical side, your data will be secured.

- What technologies does Django Stars use to build inventory management software?

Django Stars is a Python- and Django-focused inventory management software development provider with a multi-stack expertise.

This means that we predominantly use Python’s Django framework for backend development, but we also specialize in a range of relevant front-end libraries, like React or Vue.js, scalable databases, cloud deployment tools, APIs, design platforms, and integration methods.

- What are the common challenges in inventory management software development, and how to overcome them?

The most pressing challenges in building inventory management software include:

- Inaccurate or inconsistent data from legacy systems

- Integration with existing ERP, WMS, or e-commerce systems

- Balancing flexibility (many features) and complexity (slower implementation)

Django Stars’ guidance emphasizes the adoption of features to actual business processes instead of over-engineering.

- What are the top trends in inventory management software?

- The main trends in inventory management software development right now include real-time inventory visibility and analytics via IoT sensors. There is a lot of demand for AI forecasting and automated replenishments. Also trendy are cloud-native and mobile-friendly IMS solutions for remote warehousing and multi-site tracking.

- Should I choose off-the-shelf or custom-developed inventory management software?

It depends on what scale you expect, how unique you want IMS to be, and your future growth plans. Off-the-shelf solutions are faster and cost-effective for standard workflows and smaller businesses. Custom-developed software makes sense when you seek authenticity and deep integrations, or plan to scale extensively.

Django Stars notes that around 95% of e-commerce firms may start with off-the-shelf, but custom becomes perfect for bespoke logistics demands eventually.