Maritime Digitalization in Action: Odin Marine’s Journey with Django Stars

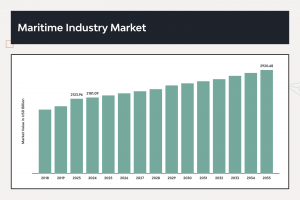

The global shipping industry is the multi-trillion-dollar circulatory system of our economy—vast, indispensable, and steeped in tradition. Roughly 80% of the world’s merchandise trade by volume still moves by sea, underscoring how central this industry remains to global commerce. Yet despite its size and importance, shipping has long been viewed as an “old dinosaur business,” operating on tradition rather than innovation.

For decades, this inertia was not a weakness but a form of stability. A shipowner’s toolkit often consisted of little more than a table, a paper map, and a telephone. Business moved at its own rhythm, and clients accepted it. But today’s shipping landscape is shaped by very different forces: volatile supply chains, stricter environmental regulations, geopolitical shocks, and clients who expect immediacy.

In this environment, tradition no longer offers resilience — it creates vulnerability. Companies unwilling to adapt risk being outpaced by competitors who embrace digital tools. Yet paradoxically, this same conservatism opens opportunities: when so many players remain stuck in outdated practices, digital first movers can leapfrog ahead, gaining durable advantages in speed, compliance, and efficiency.

That is exactly the path chosen by Odin Marine Group, a global ship brokerage with more than 100 experts worldwide. Facing the paradox of modern shipping — where its most valuable intelligence was buried in unstructured messenger chats and emails — Odin decided to confront the chaos directly. With Django Stars as its technology partner, the company turned messy communication into a structured advantage, building not only new systems but a new operating philosophy. Their journey reveals how digital transformation in shipping really works — and what lessons apply across any legacy industry.

Odin Marine’s Paradox: Intelligence Trapped in Chaos

Every organization says it wants “better data.” But Odin Marine’s discovery was that their most valuable data wasn’t missing — it was hiding in plain sight.

As ship broker Andrii Kaplia explained in the interview: “In those groups there is no particular pattern. There’s no specific format… It’s not always the market information.” And yet, this was precisely where the fastest, most time-sensitive signals appeared: conversations about vessel availability, sudden port restrictions, or shifts in cargo flows.

This situation is not unique to shipping. Across industries, the richest insights often surface first in informal channels: Slack threads in IT companies, WhatsApp groups among commodity traders, or email chains between engineers in energy companies. The instinctive response is to impose structure — to demand standardized reporting or centralized databases. But as Odin realized, this often kills the speed and nuance of natural collaboration.

Instead, Odin pursued a different strategy: build technology capable of extracting value from unstructured, chaotic communication without forcing brokers to change how they work. This was not just a technical challenge but a philosophical one. It acknowledged a truth most companies ignore: perfect data rarely exists; the real advantage comes from working intelligently with imperfect but predictive signals.

From Chaos to Responsiveness: Why Speed Is the New Currency

Recognizing that intelligence lived in informal communication was only step one. The harder challenge was delivering those insights quickly enough to matter. In shipping, speed is not cosmetic — it is existential.

A slow broker response can cascade into millions in lost value: idle tankers, wasted port fees, delayed cargoes, and frustrated clients. Andrii captures the shift vividly: “One table, a map on it, and a phone — that’s it. That’s how the business was run.” That world is gone. Today’s brokers are expected to deliver not just accurate insights, but immediate ones.

Odin Marine’s digital transformation project was not launched to chase buzzwords, but because the market punished delay. “Odin is an innovative company, so we would like to be pioneers… to be ahead of our competition,” Andrii explains.

This urgency mirrors global shipping’s broader trajectory. Real-time data from AIS, weather satellites, and IoT sensors now feeds into ML models that optimize voyages and forecast demand. Predictive maintenance reduces downtime, while AI-driven route planning can cut fuel consumption.

Meanwhile, low-earth-orbit (LEO) satellites have transformed connectivity at sea, making it possible to stream sensor and performance data continuously between ship and shore.

In other words, responsiveness has become the new currency of competitiveness. And as Odin realized, responsiveness is not about replying faster — it is about preventing the downstream costs of delay.

Radical Clarity: Turning Complex Projects into Success

Knowing what you need and achieving it are two different things. Digital transformation in conservative, high-stakes industries often fails not because of technology but because of misalignment between business leaders and engineers.

Odin avoided this fate through what Andrii described as an “overly detailed” project plan developed with Django Stars. To some, that level of detail might appear excessive. But in this context, it was a sign of competence and a source of trust.

The plan broke the project into granular stages: milestones, cost estimates, risks, and dependencies. For brokers, it explained how workflows would evolve. For executives, it clarified financial exposure. For developers, it mapped technical requirements.

In shipping, where cross-border compliance mistakes can trigger audits or fines, radical clarity is not bureaucracy. It is insurance. Odin’s experience underscores a principle too often overlooked: the more conservative and regulated the industry, the more granularity you need to unlock innovation safely.

The Role of AI: Invisible, Embedded, and Human-Guided

With a centralized system in place, the next logical step was AI. But here again, Odin Marine took a measured approach. Andrii acknowledges AI as a “must have” for efficiency but warns: “AI is definitely a helpful tool, but I wouldn’t rely on it yet… I would just stick to strategizing and using the expertise of the professionals.”

In shipping, as in finance or healthcare, the role of AI is to automate volume — not judgment. Algorithms can crunch sensor data, optimize routes, and flag anomalies. But strategic decisions — when to reroute a vessel, how to handle a geopolitical disruption, how to negotiate a complex contract — remain firmly human territory.

The mistake many companies make is treating AI as a showcase tool. A prototype that produces insights on a dashboard looks impressive but rarely changes real behavior. The value appears only when AI is embedded invisibly into workflows brokers already use: TMS systems, EDI platforms, compliance dashboards.

The broader lesson is clear: AI proves potential in prototypes, but it proves profit only when invisible, integrated, and guided by human expertise.

Emerging Technologies Shaping Marine Shipping

Odin’s transformation reflects a broader wave of digitalization sweeping global shipping. Several technologies are reshaping how fleets, ports, and inland waterways operate:

IoT and Connectivity

Modern vessels carry hundreds of sensors monitoring engines, cargo, and navigation. With LEO satellites and portside 5G, ships can now stream real-time performance data to shore-based control centers. Inland barges connect via land networks, feeding data into River Information Services that optimize traffic flows.

Automation and Autonomy

From autopilot algorithms to autonomous ferries, automation is advancing rapidly. Ports are deploying robotic cranes and automated truck gates to speed turnaround. Inland trials of unmanned barges and tugboats are underway.

Digital Twins

Virtual replicas of ships and port systems are gaining traction. These twins ingest real-time data to simulate performance, enabling predictive maintenance and design validation. While adoption is still early, digital twins promise significant cost savings by catching inefficiencies before they become failures.

Blockchain and Smart Contracts

Distributed ledgers are being piloted for bills of lading, insurance, and customs documents. Platforms like CargoX and other eBL solutions show how blockchain can cut document processing dramatically, while ensuring transparency and tamper-proof records.

Integrated Systems

Perhaps less flashy but equally vital, shipping is moving toward single-window platforms where carriers, ports, and regulators share data seamlessly. Integrating shipboard systems with TMS and port community systems is essential for true end-to-end supply chain visibility.

While these technologies share a common goal—reducing uncertainty, compressing timelines, and enabling sustainability—their success hinges on overcoming barriers.

Challenges and Risks of Implementation

Technical Risks: Connectivity at sea remains patchy in many regions. Integrating modern sensors with aging ships is complex. Cybersecurity is a growing threat as more ships become connected. Standardization across platforms is still lacking, hindering interoperability.

Organizational Barriers: Shipping remains a conservative industry. Many companies face high upfront costs, lack of digital skills, and cultural resistance to change. Fragmentation across carriers, ports, insurers, and regulators makes collaboration difficult.

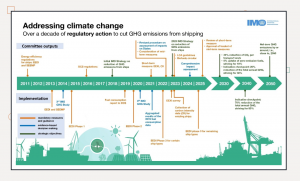

Regulatory Uncertainty: Innovation often moves faster than regulation. Rules for electronic bills of lading, for example, are still evolving globally. Data privacy laws complicate ledger-based approaches. At the same time, new sustainability regulations (IMO’s decarbonization targets, EU ETS, CSRD) force companies to implement real-time emissions monitoring.

Ecosystem Gaps: Data silos remain pervasive. Different ports and carriers use incompatible systems, slowing integration. Without agreed standards, pilots often stall before scaling.

These barriers aren’t theoretical—they’re the reasons most pilots stall after a demo. The way through isn’t more technology; it’s governance and operating discipline: a single accountable owner, a phased plan with go/no-go criteria, explicit data contracts between ship and shore, and security/compliance built in from day one. That is what we mean by radical clarity. When organizations do this well, they don’t just “launch a tool”—they change how decisions are made at the edge (on the bridge, in operations, at the terminal).

What changes when you get that right? Three things you can measure immediately: faster and more reliable operations, lower compliance effort and risk, and a sustained reduction in fuel/emissions intensity. Those outcomes are the point of the tech—and they’re what we turn to next.

Revised opening to Impacts on Operations, Compliance, and Sustainability

Because the program is governed with clear owners, data contracts, and embedded controls—not just new software—impact shows up in the KPIs that matter:

Operational efficiency (minutes/hours)

- Before: Brokers and captains wait on manual updates from scattered chats and emails.

- After: The same signals are captured and surfaced in the tools they already use, cutting time-to-answer and reducing knock-on delays (berth windows, tug schedules, demurrage).

- KPI examples: ETA error variance ↓, port stay variance ↓, unplanned off-hire ↓, predictive maintenance hit rate ↑.

Compliance (accuracy and auditability)

- Before: Quarterly scrambles for fuel/emissions logs and certificate evidence; high audit friction.

- After: Automated capture from sensors/AIS with policy checks at ingest; evidence is generated as a by-product of operations.

- KPI examples: time-to-compile regulatory reports ↓, data reconciliation exceptions ↓, successful audit samples ↑.

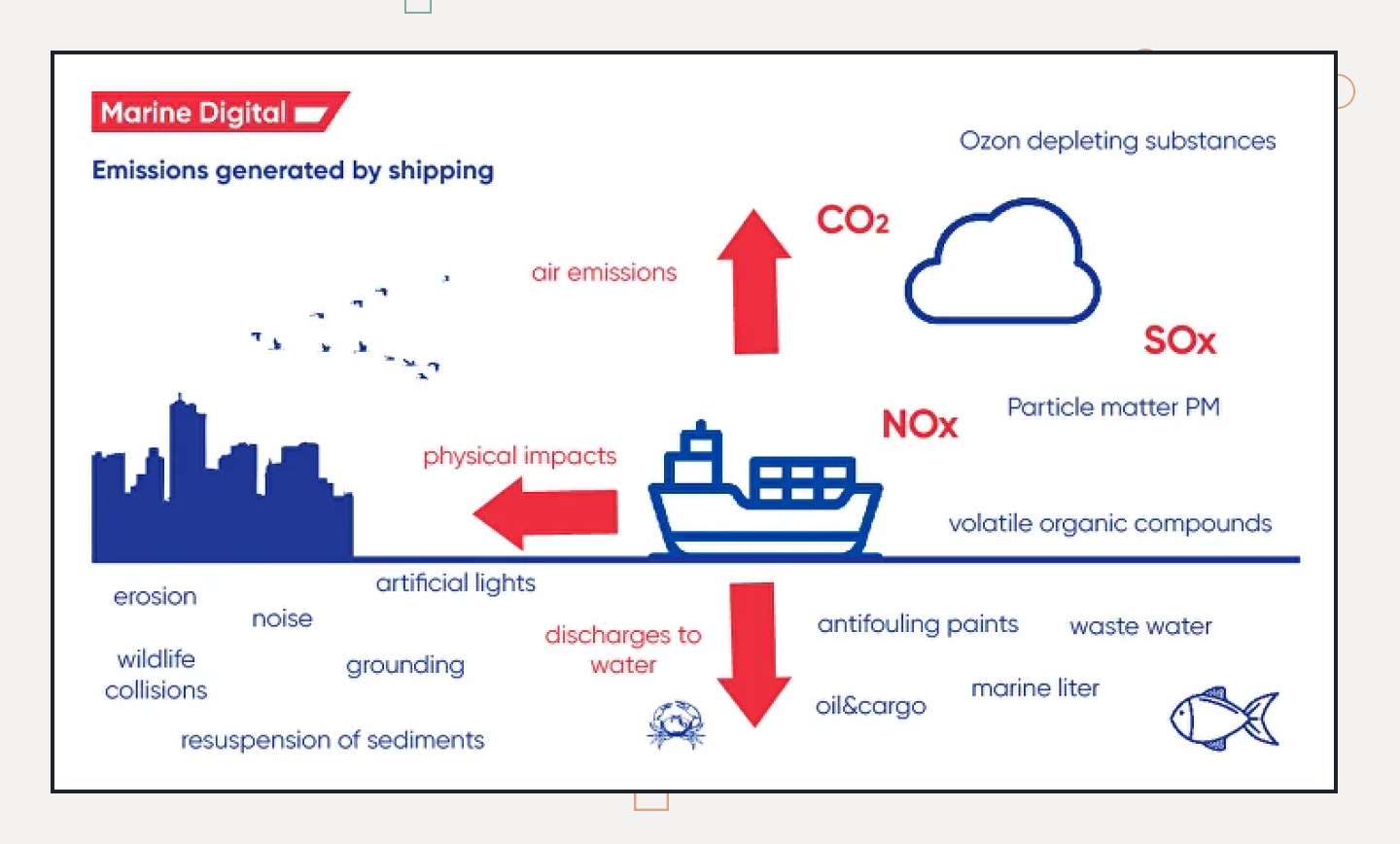

Sustainability (intensity, not slogans)

- Before: Speed/fuel decisions optimized locally and heuristically.

- After: Voyage optimization and condition monitoring inform routing and hull/propeller care, lowering fuel per ton-mile.

- KPI examples: grams CO₂ per ton-km ↓, fuel per nautical mile ↓, eco-speed adherence ↑.

Taken together, these gains—faster turnarounds, lower audit friction, and sustained emissions intensity reductions—move the organization from firefighting to repeatable performance at scale. But this is also where many programs hit a ceiling: the first wins come from point solutions; durable advantage requires turning those wins into a platform that every voyage, vessel, and port touchpoint can benefit from. That is the hinge from “measurable impact” to “systemic advantage,” and it’s exactly what the next phase demands.

The Next Frontier: From Local Wins to a Fleet-Wide AI Platform

If the impacts above are the what, scaling is the how you make them universal—without creating dashboard sprawl or compliance risk. The rule of thumb: don’t add more models; add more reliability. In practice, that means productizing the early use cases into a governed platform that your brokers, captains, and ops teams experience as one system, not ten pilots. The disciplines that separate durable programs from “good demo, no runway” are consistent across fleets:

Platform, not projects—Promote successful pilots into a shared services layer (data ingestion, feature store, model registry, alerting) so every new use case reuses the same plumbing.

Contracted data flows—Treat ship-to-shore data as APIs with SLAs: schema versioning, quality checks at ingest, and auto-quarantine for bad data—so models don’t silently degrade.

In-workflow delivery—Surface predictions inside TMS/EDI/bridge tools already in use. No new tabs unless they replace an old one. Adoption follows friction reduction.

Human-in-the-loop by design—Brokers and masters remain the decision owners; the system must capture overrides and learn from them (feedback loops, post-decision analytics).

MLOps and model risk management—Version everything, monitor drift, retrain on schedule, and keep audit trails for regulatory and client assurance.

Security and compliance baked in—Role-based access, encryption, and evidence generation as a by-product of operations—so scaling does not outpace control.

Proof before propagation—Expand use cases only after a contained A/B or shadow period shows KPI lift (fuel/ton-nm, ETA variance, demurrage, time-to-report).

Handled this way, “AI at scale” isn’t a collection of clever tools; it’s a reliable operating layer that makes the earlier operational, compliance, and sustainability benefits the default everywhere in the network.

Conclusion: From Legacy to Lightning Speed

Shipping may still be called a dinosaur industry, but as Odin Marine proves, even dinosaurs can move at lightning speed when tradition and technology are fused with discipline. The question for every leader is no longer whether to digitize — that debate is settled. Partner with Django Stars to design and deliver the custom software your operations actually need—integrated TMS/EDI workflows, compliance-ready data pipelines, AI-assisted tools embedded in daily processes, and cloud platforms that scale with your fleet. Build it right, ship faster, and stay ahead.