Predictive Analytics in Logistics and Supply Chain Management Software

What’s worse for a business than a pile of goods gathering dust in a warehouse when they’re needed elsewhere? Or a truck hauling fresh produce breaking down in the heat? These are exactly the problems predictive analytics in logistics helps avoid.

Predictive analytics as a whole is enjoying a boom, and it’s not one of the supply chain software trends, with forecasts predicting a healthy 20.4% CAGR for the market sector between now and 2028. Analytics software solutions help streamline and centralize real-time data processing to drive business decision-making and growth.

That’s good news for everyone, but especially for logistics companies, who happen to generate data in spades — from invoices, docking schedules, and maintenance reports to data on truck fleet mileage, inventory stockpiles, and weather forecasts.

The ability to dissect this data and turn it into actionable business insights is one of the key benefits of predictive analytics in the supply chain. The predictive analysis enables logistics operators to reduce losses, minimize risks, and meet customer demand more efficiently. This is why many companies are turning to predictive analytics in the custom supply chain management software and logistics to survive the coming recession.

At Django Stars, we’re no strangers to the challenges of logistics management. It was a key feature we developed for a leading US-based corporate meal delivery company. We helped build a highly scalable and reliable system that orchestrates workplace meal delivery and keeps suppliers efficient regardless of the size of a customer’s demand.

This article explores the market landscape of predictive analysis in transportation and logistics, the benefits of logistics analytics solutions, and the challenges a company can face when implementing them.

We’ve decided to share this information because we often encounter similar matters while delivering logistics software development services. The recommendations provided might also prove beneficial to you.

What is predictive analytics in logistics?

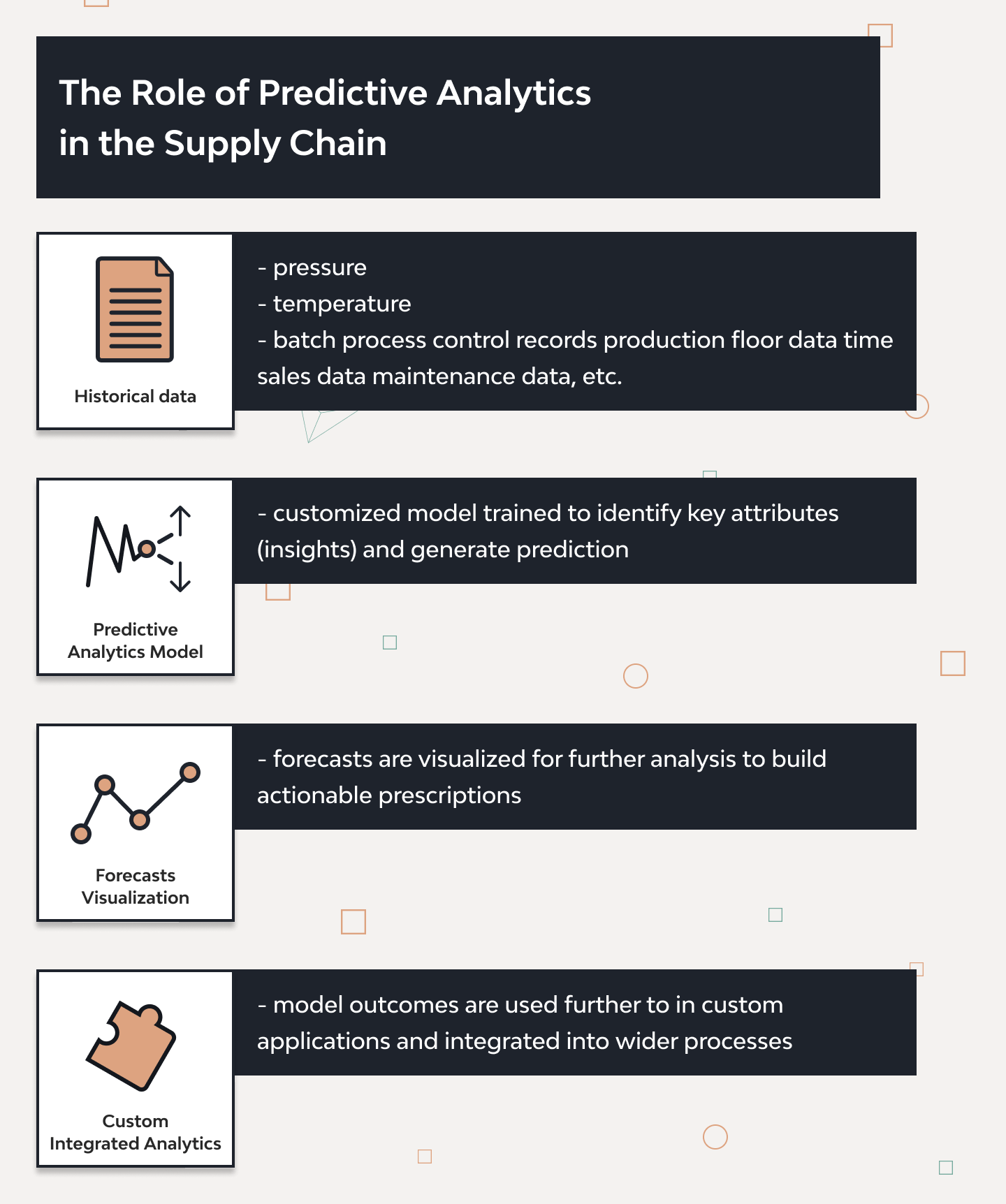

Predictive analytics in logistics is the use of historical data, statistical models, machine learning, and a variety of external signals to forecast future events, demands, risks, and trends throughout the supply chain. That is what puts it apart from descriptive analytics (describing what happened) and diagnostic analytics (diagnosing why something happened).

Instead, predictive analytics allows answering: “What is likely to happen next?” and “What potential challenges or demand spikes should we anticipate?”

Using predictive analytics in logistics industry enables companies to discover actionable insights in their own data from past shipments, inventory records, and a variety of performance metrics accumulated over time. Perhaps that is why its global usage has grown dramatically.

The growth of the transportation predictive analytics market

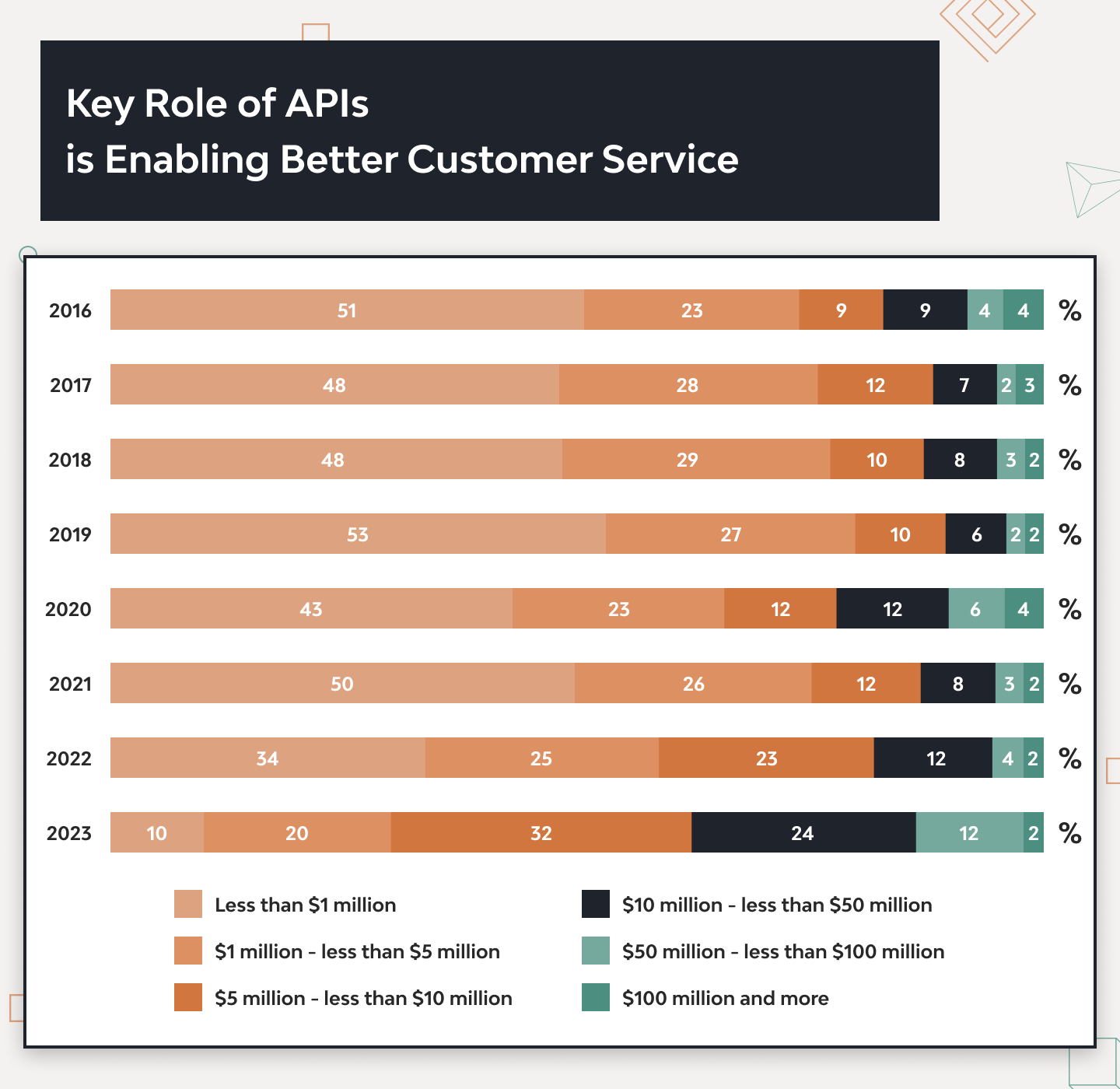

Many factors have contributed to the stable growth of predictive analytics in supply chain market over the recent years. While economic feasibility has been key, technological availability and business future-proofing have also played a crucial part.

The COVID-19 pandemic highlighted the importance of contingency planning and company flexibility for coping with sudden supply chain limitations. According to a series of MHI and Deloitte reports on the supply chain and logistics industry, in 2017, only 30% of supply chain managers were using software to support data-driven decision-making. By 2022, this percentage had grown to 54%.

These reports highlight five key applications of predictive analytics in the logistics industry in 2023 and beyond:

- Demand forecasting (39%)

- Maintenance and asset management (35%)

- Customer interaction transparency (35%)

- Supply planning (32%)

- Pricing (31%)

Elsewhere, 2022 research into the predictive analytics market places the market size at $12.5 billion in 2022 and forecasts it will reach $38 billion by 2028.

Finally, recent advances in cloud-based supply chain management software and the efficiency of Big Data analytics have made solutions for predictive analytics more affordable and accessible to small and medium businesses. This puts the power of supply chain predictive analytics in the hands of almost any SMB looking to increase its operational efficiency.

Benefits of predictive analytics in logistics and supply chain

While predictive analytics has been around since the invention of computers, for decades, the sector struggled with limited datasets and reliance on historical data that was often hidden in obscure formats.

Nowadays, predictive analytics for supply chains can combine unstructured data from a huge variety of disparate sources, analyze it in real-time (or near real-time), and provide actionable, easily visualized insights on the go. This makes analytics accessible to every business, even those with no data analyst expertise.

Here are just some of the benefits of predictive analytics in logistics and other industries, with examples of how they’ve helped companies to thrive.

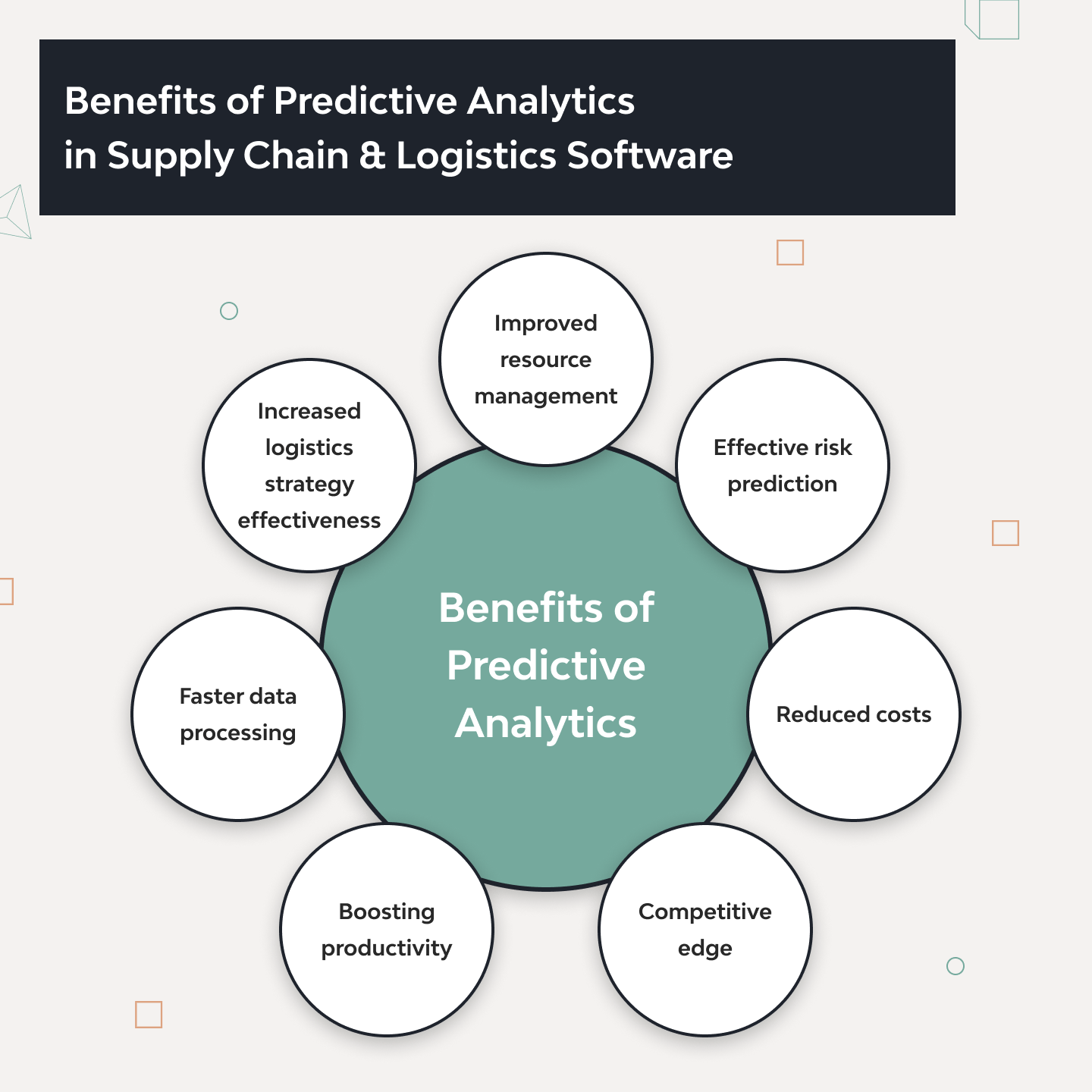

Boosting productivity

One of the biggest value drivers of predictive analytics is its ability to identify bottlenecks in processes. In turn, this helps remove inefficiencies and optimize business processes.

New Jersey healthcare provider Atlantic Health saved $70 million in labor and premium costs in three years by implementing a predictive analytics system. They were able to analyze labor costs and predict hospital productivity, which resulted in better patient outcomes, earlier discharges, and shorter hospital stays.

Faster data processing

Data is only valuable if a business or customer can act on it while it’s relevant. Enabling the timely application of corrective action is what makes analytics software useful.

Harvard University’s Project Abbie sensor technology analyzes patient vitals in real-time to detect early signs of anaphylactic shock caused by an allergic reaction. The sensor then sends a signal to a wearable device to administer a dose of epinephrine. It’s an example of early detection and fast data processing being used to literally save lives.

Increased logistics strategy effectiveness

Excess inventory means money wasted on storage, while stock-outs mean lost revenue. Using predictive analytics in supply chain management allows companies to accurately predict spikes in demand and address them fast.

PepsiCo’s Sales Intelligence Platform keeps track of stock at every one of its vendors and lets retailers know in time that they need to replenish, ensuring maximum efficiency of the company’s supply chain.

Improved resource management

Then again, simply having the needed resources somewhere is not enough. They also have to be instantly accessible when a customer needs them.

As far back as 2014, Amazon was already patenting its famous anticipatory shipping technology, which relies on logistics predictive analytics to anticipate the demand in any Amazon hub area based on historical data and real-time factors. This helps the company optimally distribute stock and enable one-day customer delivery.

Amazon’s solution also calculates the number of drivers needed daily, the routes they should take, and even the way the delivery vehicles are loaded, so the driver spends less time searching for the next parcel, improving last-mile delivery efficiency.

Effective risk prediction

While predictive analytics shines in fighting cybercrime and supply chain fraud, it can be used in any risk mitigation process. Currency exchanges use prediction tools to mitigate volatility caused by political events. Logistics companies, in turn, can enhance their plans and schedules with risk alerts based on weather forecasts, equipment maintenance status, and other factors.

Back in 2015, one in three shipping containers was transported empty, costing Danish shipping giant Maersk and Germany’s DHL billions of dollars annually. In 2018, DHL invested $350 million to build MySupplyChain — a predictive analytics platform aimed at optimizing and digitalizing their operations.

Reduced costs

The empty container problem is nothing new. When export-oriented countries ship goods or raw materials to import-oriented countries, empty containers must be shipped back for the next haul. This implies costs of ownership, costs of transportation, and costs of repositioning, as empty containers still require ships to deliver them while carrying no goods. These costs amount to over $20 billion yearly for the top 100 logistics companies worldwide.

Maersk Line, a shipping giant responsible for transporting nearly 15% of annual global GDP, developed a proprietary solution for predictive analysis in transportation to ensure they use their fleet with utmost efficiency and can relocate empty containers in time to meet demand.

Competitive edge

All of the above benefits help companies better allocate resources, minimize losses, meet customer demand, and stock inventory more efficiently. Predictive maintenance of equipment and vehicles also improves a company’s bottom line, as it reduces transportation downtime and increases operational capacity.

Recent research from the University of Athens highlights the efficiency of using non-destructive control methods and IoT sensors to determine the condition and expected life span of all company equipment. This enables timely and relevant maintenance instead of facing engine failures on the road.

By keeping its fleet operational, keeping a healthy stock of supplies, and optimizing resource allocation, any logistics company can gain a competitive edge. Here are some more use cases for predictive analytics in supply chain management.

Use cases of predictive analytics in logistics industry

How do the business benefits we’ve covered above translate to real-world gains? Let’s look at some key use cases and examples of predictive analytics in supply chain.

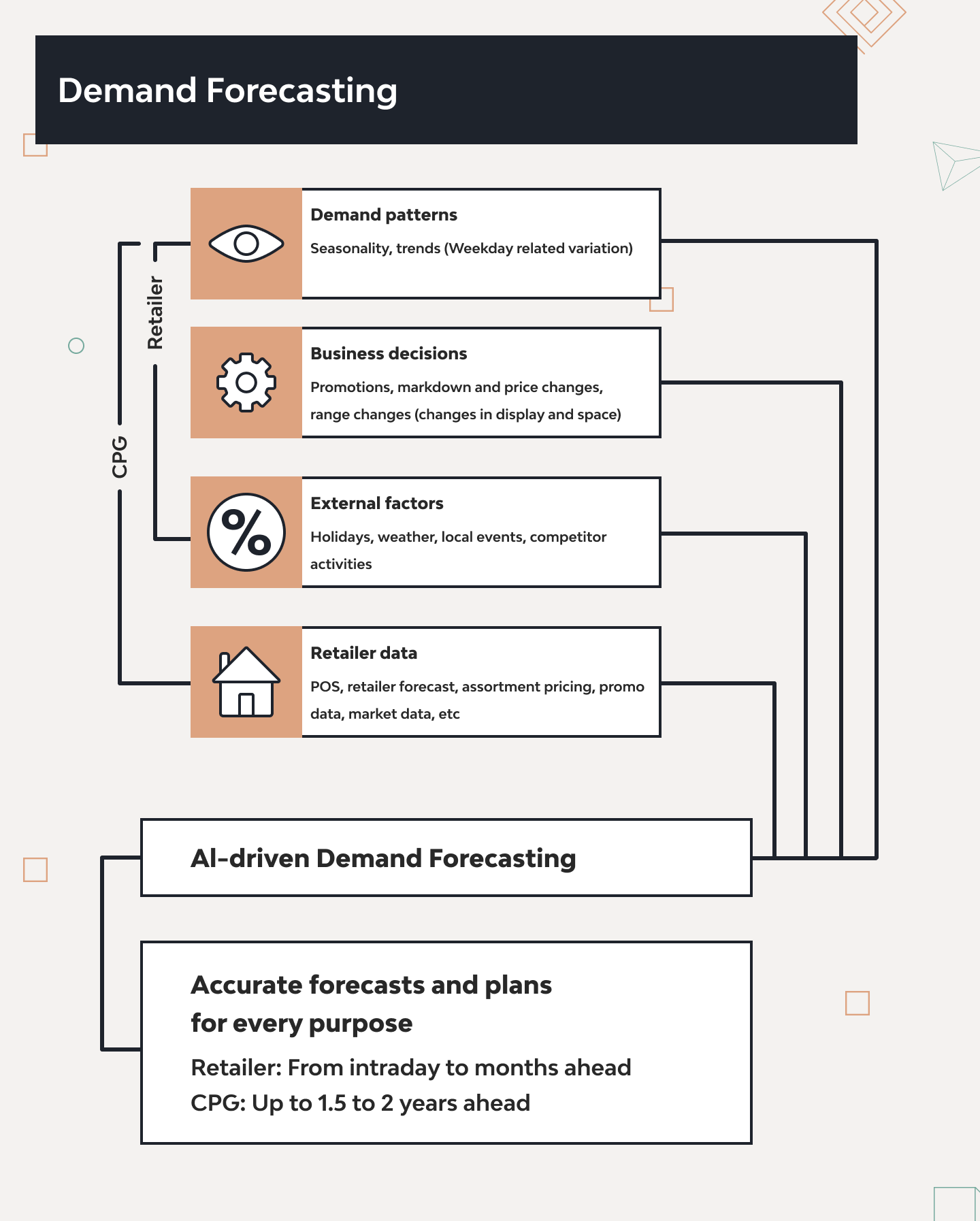

Demand forecasting

Combining historical data with real-time insights based on seasonality, news, natural disasters, or political events can help logistics companies make data-driven decisions.

For example, if historical data shows that people eat more grains in winter, retailers can stock up in late fall to prepare for the seasonal surge. However, it’s also important not to overstock in order to leave storage space for other products and avoid warehouse costs. Demand forecasting uses past data to make more accurate stock level forecasts and ordering suggestions for retailers.

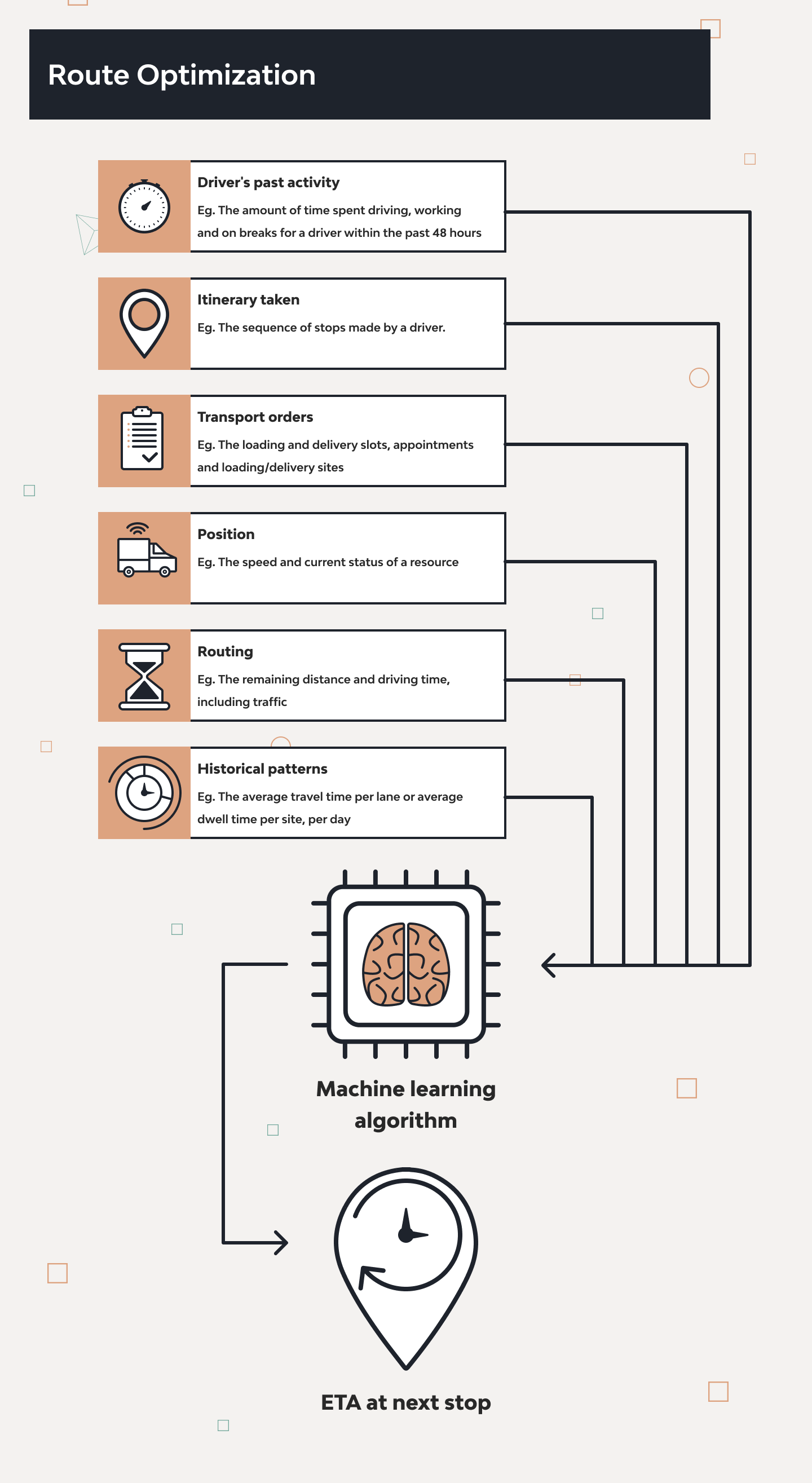

Route optimization

Long-range trucking is an essential aspect of logistics. To be efficient, it requires full transparency of every aspect of a company’s trucking operations. A lot of it can be achieved through the use of predictive analytics in supply chain.

E.g., factors such as weather conditions, gas mileage, driver’s health (sleepiness), truck condition, and load all weigh into the selection of the best route. Monitoring these through smart sensors, integrated communication channels, and IoT devices helps mitigate risks and ensure optimal route planning. UPS is an example of optimizing delivery routes using predictive analytics.

Inventory management

Allocating resources where they are really needed is one of the key benefits of predictive analytics in the supply chain. Alibaba, Amazon, DHL, and other shipping companies use smart sensors and RFID codes to track their freights and vehicles en route. It enables them to know which order is where and the ETA for each delivery. It also ensures there are no jams at depots, as truck arrivals and departures can be intelligently scheduled, demonstrating the relevance of predictive analytics in logistics.

Maintenance scheduling

As we’ve already seen, carrying out timely maintenance based on historical incident data and information from smart sensors can help prevent major equipment breakdowns. The challenge here is to share data with the spare parts provider and retailer so that replacement parts can be delivered before the engine or any other system fails. This requires building secure data exchange channels through a collaborative platform, which takes time but ultimately improves processes all around.

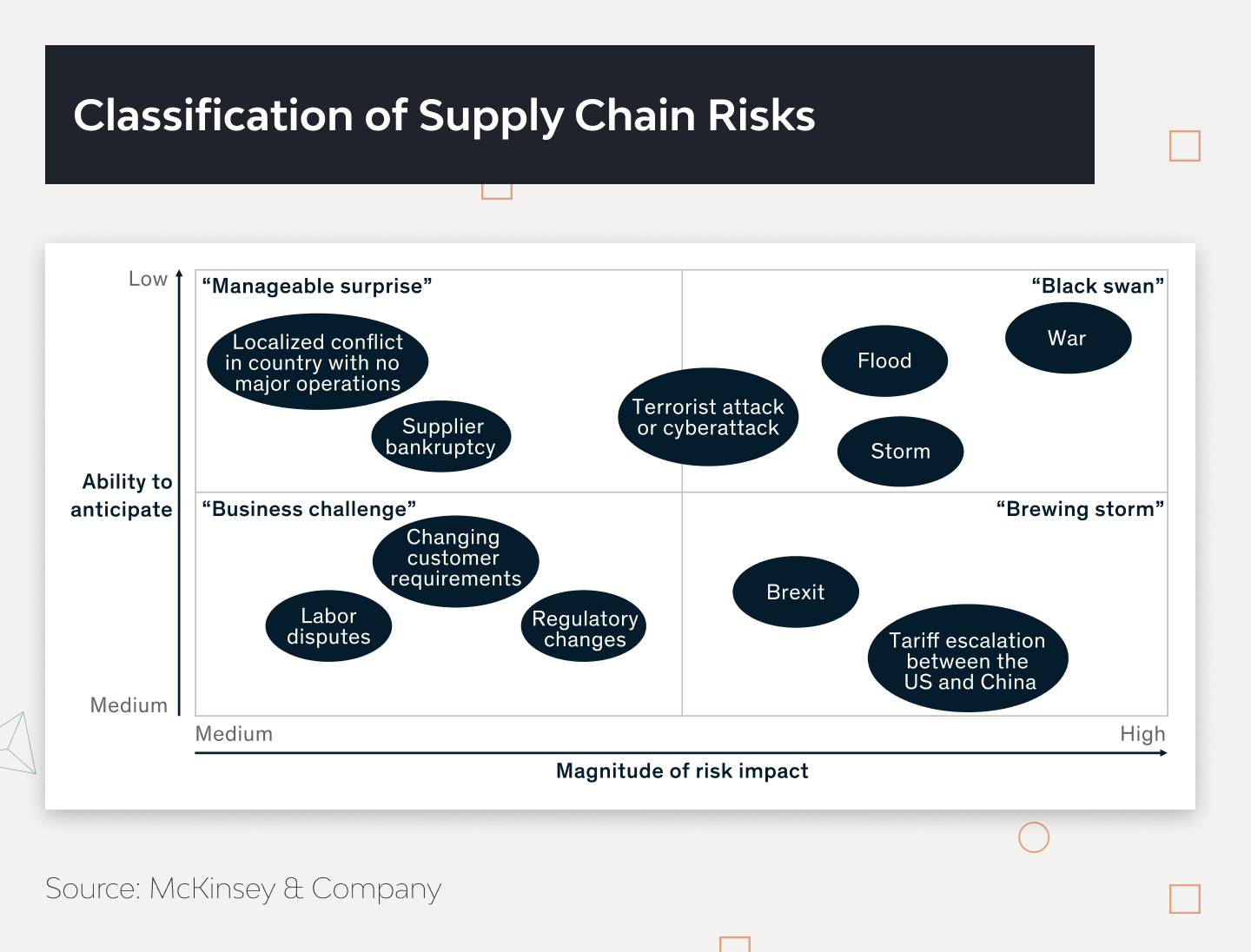

Risk management

Risk is intertwined with business opportunities. Some events — such as natural or technological disasters, human conflict, or the passing of a new law — lie outside the control of supply chain operators. However, other risks can be foreseen, meaning that intelligent analytics platforms can use them to shape better contingency plans and recommendations.

All these use cases help use predictive analytics in logistics to optimize the operational efficiency of any supply chain operator. But there are two sides to every coin, and these benefits come with some challenges.

Challenges of implementing predictive analytics in logistics and supply chain

Here are the primary challenges of adopting predictive analytics in logistics industry today:

- Poor data quality: When implementing predictive analytics in supply chain, there is a common lack of relevant historical data. Even when data does exist, it’s often siloed and disparate and can’t be easily structured to form a training data set for an AI algorithm. Manually entered data, confusing spreadsheets, or legacy systems are often filled with duplicates, typos, inconsistent naming conventions, or mismatched fields. Such dirty data can make analytics models generate poor predictions.

- Data integration across systems: Logistics operations generate data from many sources, including warehouse and fleet management systems, ERPs, external partner data providers, IoT sensors, manual logs, etc. It all needs to be aggregated into a unified analytic system. Out-of-date systems add to the challenge, but even if you work with non-legacy solutions, source data will be coming in both structured and unstructured. You will need to merge and normalize it before implementing predictive analytics in supply chain logistics.

- Data processing limitations: Learning algorithms need an in-depth understanding of all the processes involved in operations in order to decide which parameters are crucial and which can be filtered out to improve prediction accuracy. This means that you need to process data in near real time, or at least with minimal delay, if you expect the analytics to bring real value. And yet even the fastest clouds can have latency and data ingestion slowdowns.

- Data privacy and security: Using predictive analytics in logistics requires some exposure of sensitive data, like the info about clients, routes, vehicles, inventory, all the way to BI and more. Not every logistics operator has the budget or access to the necessary human resources for safeguarding data privacy and reinforcing cybersecurity. This is where vendor expertise can be irreplaceable as a fast and long-term cost-efficient solution.

How to implement predictive analytics: Key 6 steps

Define your objectives

Formulate a strategy — highlight the required data sources, and define your expectations of implementing predictive analytics in logistics.

Collect and prepare data

Collect delivery notes, sales contracts, trade deals, outstanding contracts, and other information regarding company operations.

Select tools and techniques

You’ll need a tech stack with AI/ML, collaborative, and data-processing tools to structure, filter, and pass data through the funnel.

Build and train models

The predictive AI/ML model will only work as accurately as you teach it — prioritize its training and keep it continuous well after the model’s deployment.

Test and validate models

The ML model must be able to correctly predict outcomes known from historical data — test the use of relevant data sources, speed, and accuracy of analysis.

Deploy and integrate

Once you integrate and launch the ML/AI model for predictive analytics in supply chain, the entire algorithm must be deployed to the production environment.

Django Stars: Case studies on predictive analytics in logistics

We’ve been working on solutions powered by predictive analytics in logistics industry since 2008. Django Stars are ISO certified and currently rank as the market leader in Clutch ratings of the top 50 Python & Django developers worldwide. We optimized architecture and refactored code for a leading US-based corporate meal delivery service — and built Azyan, a 20-minute food delivery platform in Jordan.

During our partnership, Azyan became one of the most popular food delivery services in Jordan, thanks to the ease of its restaurant registration process and the use of Google map coordinates to ensure accurate delivery.

Django Stars has amassed a wealth of knowledge in software development and offers flexible vendor solutions ranging from team extension to dedicated product development from scratch. We focus on building complex and feature-rich solutions that make our clients’ business processes simple, predictable, and highly scalable.

Conclusion

Supply chain predictive analytics empowers businesses to turn a flow of disparate data into an actionable input supporting data-driven decision-making. The market for predictive analysis in transportation and logistics is steadily growing as more companies digitize and optimize their operations to retain their competitive edge.

Minimizing overstocking losses and the bullwhip effect, correctly forecasting demand, reducing equipment failures with preventive maintenance, and saving on labor and maintenance expenses are just some of the benefits of predictive analytics in the supply chain. However, implementing such solutions requires in-depth development expertise to ensure the correctness and usefulness of predictions.

If you’re planning to improve your operational efficiency with logistics predictive analytics, contact Django Stars, and let’s discuss the ways we can make it happen.

- What is predictive analytics in transportation and logistics?

- Predictive analytics for transportation and logistics is a subset of data analytics that determines patterns based on historical data and predicts outcomes based on real-time input to reduce expenses and optimize efficiency.

- What technologies are used in predictive analytics for logistics?

- Predictive analytics in logistics can run on a variety of tech. Still, the core solutions include IoT sensors and telematics (e.g., GPS trackers, warehouse sensors), Big Data tools (for telemetry structuring and data processing), AI/ML algorithms (for AI model employment), cloud platforms, and tools for simulations (testing) and optimization.

- How is predictive analytics transforming logistics and supply chains?

- Predictive analytics helps both leading supply chain operators and smaller logistics companies gain improved visibility into their inventory, allocate resources correctly, and maximize their bottom line.

- What is the future of predictive analytics in logistics and supply chains?

- This market is expected to grow to $38 billion by 2028 and has the potential to save logistics companies billions of dollars annually.

- How much does it cost to adopt a predictive analytics solution in logistics?

- The cost depends on several factors: the quantity and complexity of features to implement, the existing IT infrastructure, and the complexity of synchronizing all the data sources to form a cohesive data flow. For exact numbers, contact Django Stars.