The Secret to Streamlining Operations in Logistics with Warehouse Management Solutions

In 2019, a glitch in warehouse management software cost Asos, the global fashion retailer, an estimated $25 million in a single quarter. This goes to show that it doesn’t matter how much value a product brings to customers; poor management of warehouse operations can be fatal to the bottom line.

The Asos case demonstrates that having a reliable warehouse management solution is critical for any company that depends on logistics. In fact, robust software can ward off inventory catastrophes like this and streamline operations in logistics, taking them to an entirely new level.

As a custom logistics software development company with more than 16 years of experience developing logistics solutions, Django Stars knows the problems logistics companies face and how to solve them with software. And we are eager to share the benefits of adopting a software-based warehouse management system (WMS).

Why Streamlining Logistic Operations with WMS Is Vital

Every single process in warehouse management is, in essence, error-prone. Miscalculations during receiving or picking, item misplacement during put-away, or incorrect data entry during receipt creation or cycle counts can seriously plague workflow and harm a company’s reputation.

Meanwhile, customers have become accustomed to a certain level of service. For 85% of customers, a poor delivery experience is a legitimate reason to switch retailers. Same-day or next-day deliveries are also held in high esteem. Competition adds fuel to the fire: Nine in ten warehouse managers are set to increase the use of technologies in their processes over the next five years, raising the bar for warehouse management standards. The rise of the on-demand economy is the icing on the cake: shipping volumes have increased by 20% over the past two years.

As a result, wholesalers, manufacturers, distributors, and, indeed, any businesses relying on warehouse management need to optimize their warehouse operations in terms of accuracy, productivity, and cost efficiency.

Therefore, reliable software for optimizing warehouse operations, also known as a warehouse management system (WMS), is becoming a necessity.

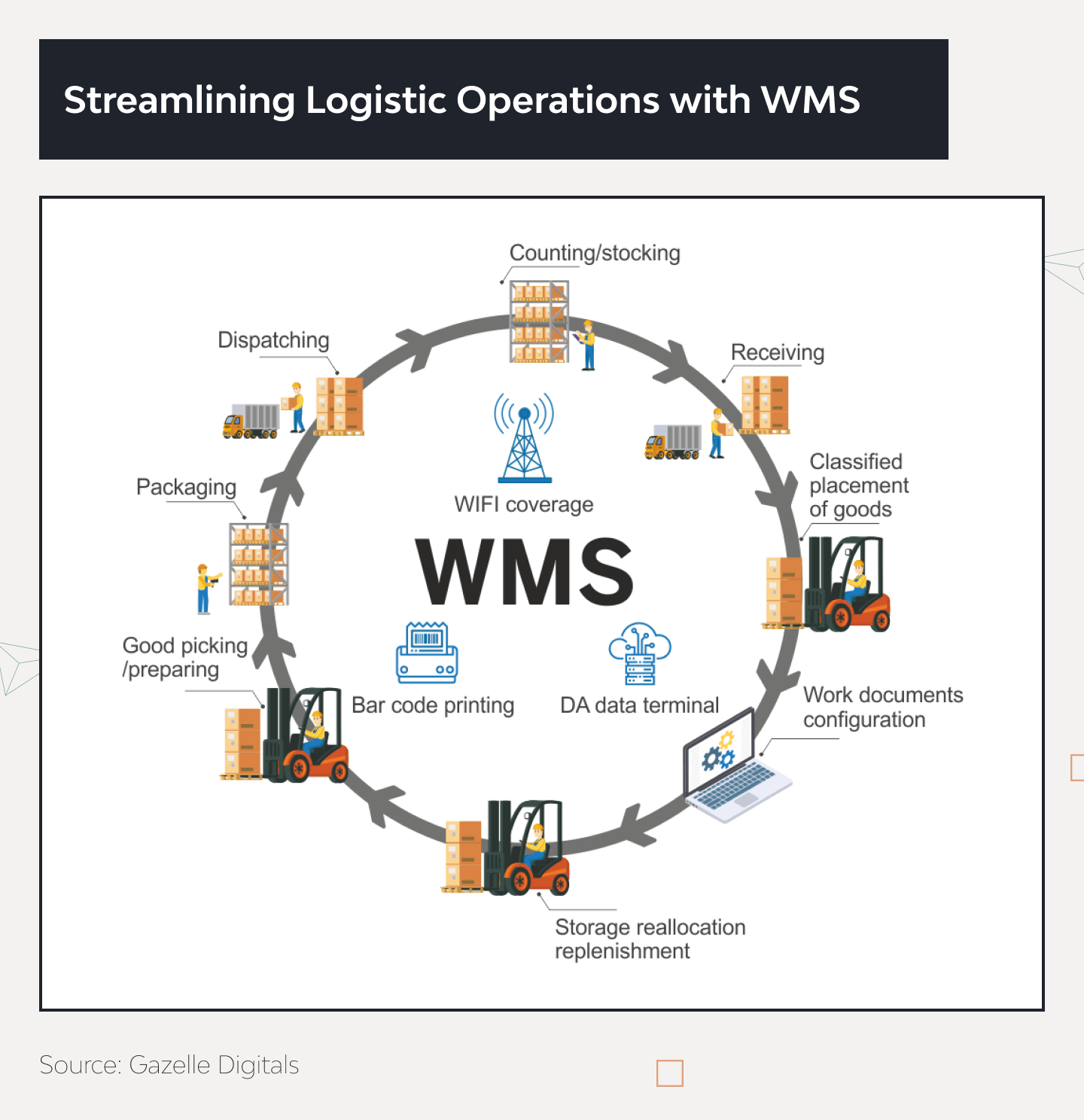

The Role of Warehouse Management Software in Logistics

Certainly, to an extent, businesses can get by without these technologies.

For example, to keep more accurate track of an inventory, supervisors can be employed at all stages of the warehouse workflow for extra checks on each item received, put away, stored, picked, and shipped. To increase order turnaround, more warehouse operators can be hired. Such steps will lead to improvements but at the expense of cost efficiency. The accompanying increased labor costs may also be reflected in raised prices for customers or partners.

However, a WMS can offer such improvements without the extra payroll burden. Let’s take a detailed look at the main benefits of warehouse management systems.

Zero silos in the workflow

Silos in data and processes can seriously hinder warehouse management workflow. They can lead to duplicated efforts, misaligned communication, discrepancies in data, reduced flexibility, and employee frustration.

Using a WMS, this challenge can be resolved. A reliable solution — supported by inventory management software development — can integrate with ERP systems, TMSs, CRM platforms, and other tools, while also connecting with IoT technologies such as barcode scanners and robots.

Automation of manual processes

Automation is a key benefit of a good WMS, contributing to all three prerequisites of seamless warehouse management workflow — accuracy, productivity, and efficiency.

A decent solution can automate the majority of processes across all warehouse operations. It can make replenishments, offer warehouse operators the most optimal route to an item’s locations, automate inventory counts, prioritize orders based on different criteria, and much more.

When implemented correctly, automation works miracles. And this isn’t an exaggeration: Cueros Vélez, a retail and fashion company in Latin America, reported a 150% increase in both height picking and the classification process after implementing Infor WMS.

Real-time visibility

Limited visibility is one of the key struggles of warehouse workers today, and a WMS can alleviate this.

Since a robust WMS collects information from all systems involved in warehouse management and serves as a single source of truth, it provides real-time visibility into all inventory levels, locations, and movements.

Case in point, Cueros Vélez reported 100% inventory visibility after the implementation of their new WMS.

Increased efficiency due to analytics

Warehouses (especially large ones) produce tons of data daily. A good WMS can analyze this information to spot bottlenecks and identify opportunities in real time. This improves the handling of:

- Stock. Aside from tracking the entire inventory in real time, it can also monitor and analyze spikes and drops in demand for certain goods. This allows for timely replenishments while minimizing the risk of overstock.

- Space. A reliable WMS will give warehouse operators recommendations for the location of each product item in a warehouse. Thus maximizing available space.

- Workforce. An automated WMS empowers personnel while reducing labor costs.

It’s no surprise that saving costs was the key reason for Mars to launch a new WMS. According to Carlos Miranda, the company’s physical logistics functional expert, the move was worth the effort and investment: “It’s incredible to see the impact our new WMS has had…”

Increased employee satisfaction

The role of a warehouse operator is challenging in itself. Lifting, carrying, walking, and traveling around the warehouse can be physical strains. In a poll that spanned 500 warehouse workers, 75% responded that physical strain outstripped mental strain in their jobs.

A WMS doesn’t just make personnel more productive. It can make their jobs easier.

Its automation functions, like route recommendations to items and prioritizing orders, can significantly decrease workers’ travel time. Moreover, robots integrated through the IoT can assist with lifting and carrying. No wonder that the same respondents considered investment in tech to be investment in themselves.

In fact, the new generation of workers is starting to consider this a baseline for accepting warehouse employment, with 73% of Gen-Z warehouse workers believing that robots have the potential to assist them in achieving greater accuracy and speed in their work.

It’s possible to significantly streamline logistics operations with a WMS. But what kind of functionalities do these benefits translate to?

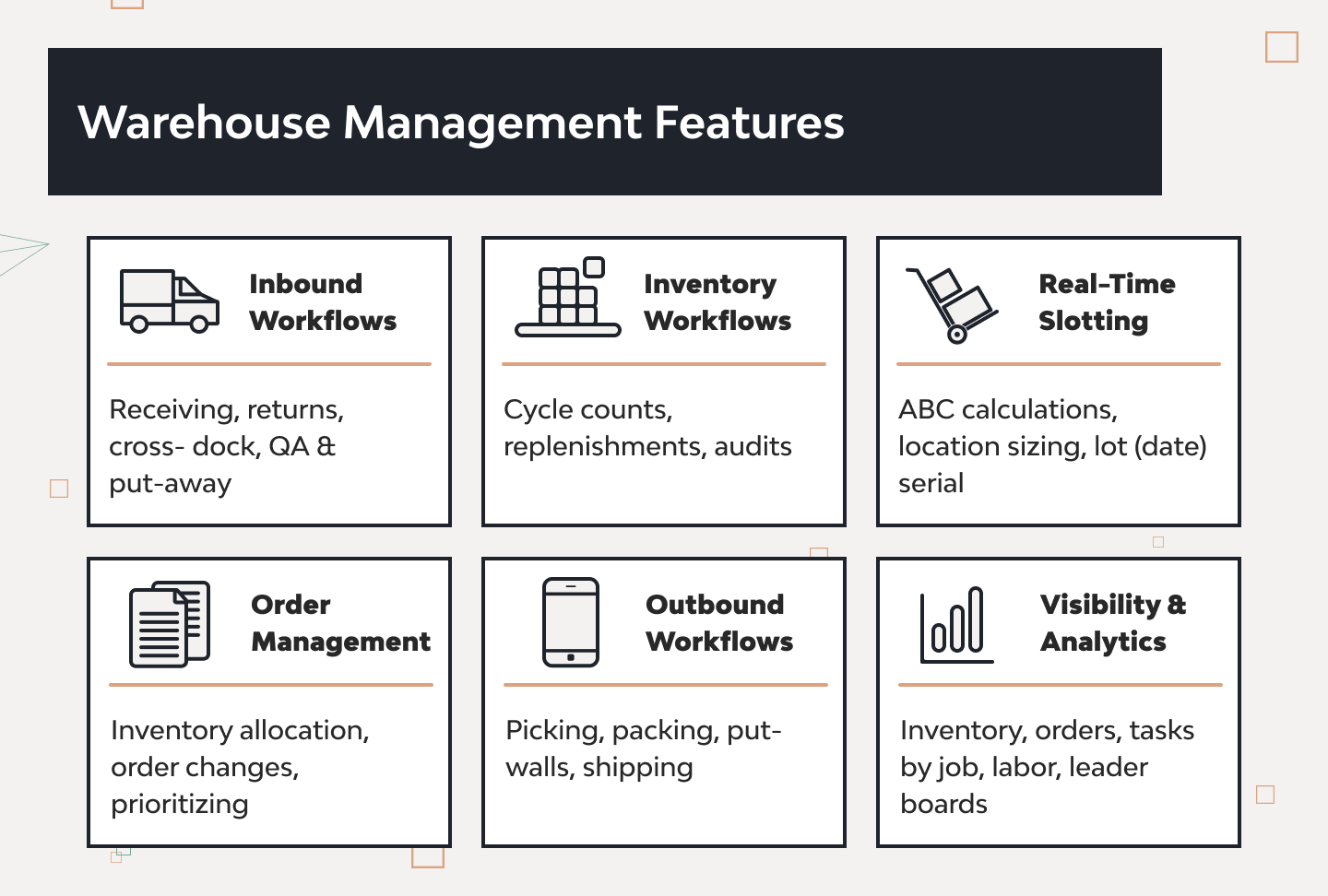

The Key Features of Warehouse Management Software

A typical WMS is a cloud-based technical solution and can be accessed from any device and location. It normally consists of several modules that mirror the main warehouse management processes — stock, sales order, and workforce management. It’s also equipped with an analytics module for better decision-making.

Let’s review each of the modules in more detail.

Stock management

- Purchase order creation. The purchase order is created manually by scanning the barcode of a respective product or automatically by a system once a pre-defined availability threshold is achieved.

- Receiving. Once the product is received and checked for discrepancies with the order, a warehouse employee scans it against the purchase order.

- Put-away. Once the product is checked into the system, a warehouse employee scans the barcode on the pallet (which contains all the information about the products on it), and the system recommends an optimal space based on the product type, demand, and other factors.

- Storage and location control. Aside from the product information stored in the barcode, the system assigns to the product its exact location details, such as area, rack, and bin. Using this information, a product’s location can be tracked and changed using a barcode scanner.

- Stock level control. As all the products in a warehouse are stored within the system, it can track item availability and recommend replenishments (or initiate them automatically).

Sales order management

- Order creation. A reliable WMS integrates with e-commerce platforms, making sales order management easier. Once a new order appears, the system will add it to the picking list.

- Picking. The system lets warehouse employees easily prioritize orders in their picking lists. It can also guide them to the needed items or delegate the picking to robots (if those integrate with the system).

- Packing and shipping. The system automatically assigns the package type to each item and truck.

- Returns. A WMS can automate product returns, updating stock levels upon each return, issuing refunds, and generating reports.

Workforce management

- Employee scheduling. A WMS can allocate tasks in a warehouse based on factors like seasonality, demand, day, zone, task type, and more.

- Performance control. Good WMSs can track the performance of employees based on KPIs such as the number of completed orders and completion time.

- Safety control. Many WMSs integrate with surveillance devices to keep track of staff whereabouts and incoming truck information. They can also limit access to certain areas or data.

Analytics

- Data analysis. A modern WMS collects and analyzes operational data to identify trends and improve planning, preventing stockouts and overstocks.

Aside from the functionalities above, a decent WMS seamlessly integrates with related platforms and connects to the hardware involved in the inventory management workflow, is designed according to all security standards, and is backed by a customer support team within easy reach.

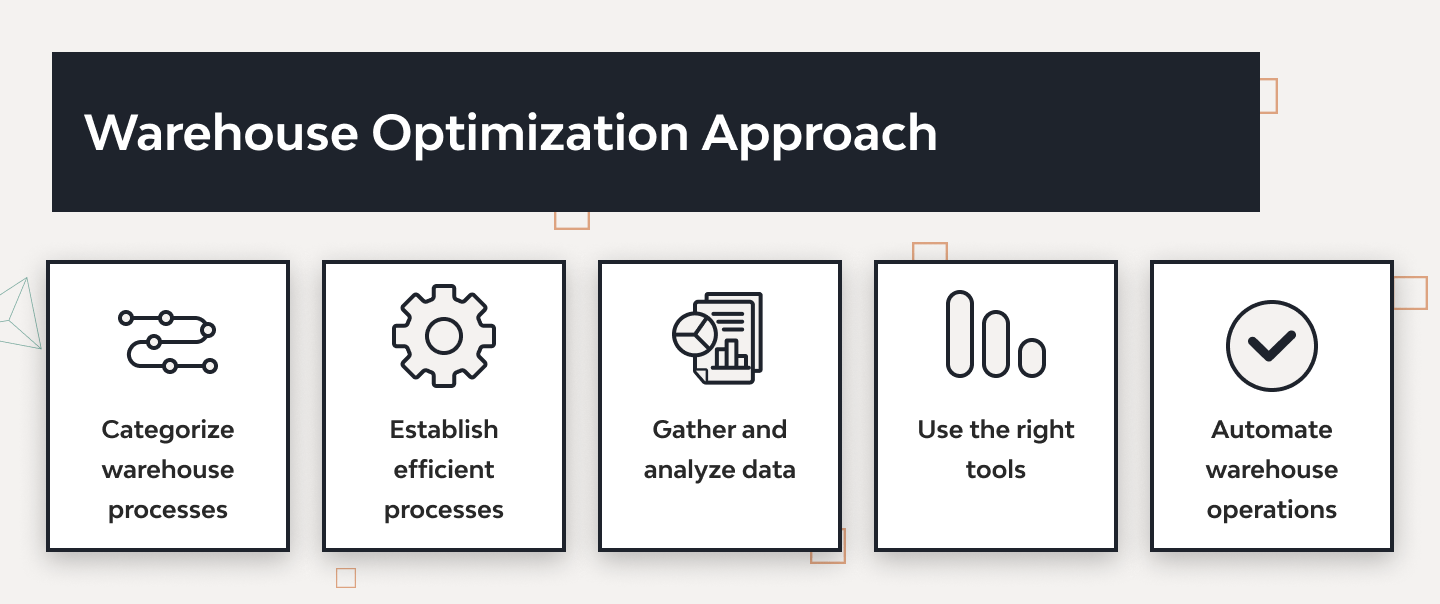

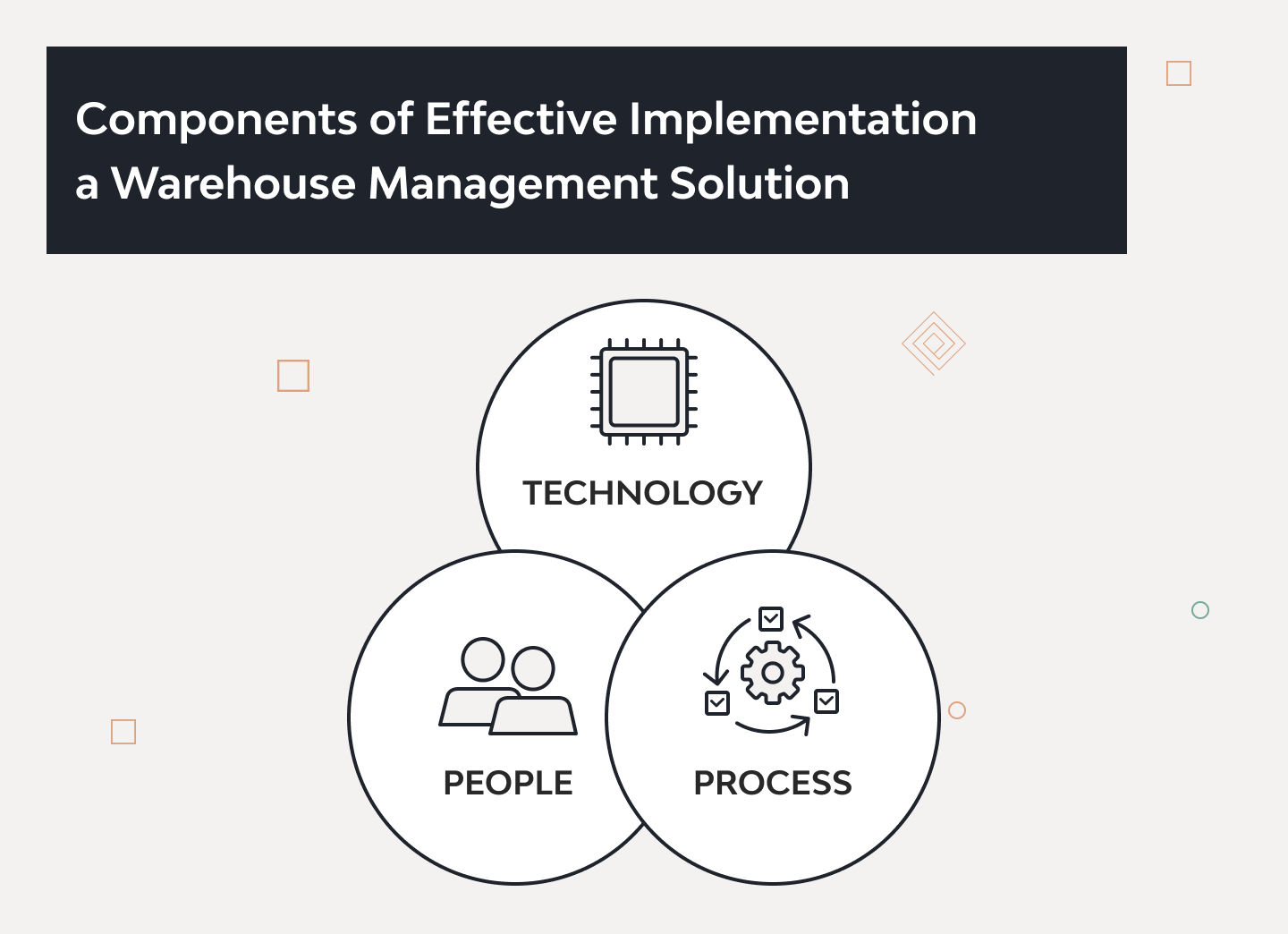

Still, having “a decent solution” is only half the battle. The method of implementation matters.

How to Implement a Warehouse Management Solution: The Key Problems

A new WMS is, in a way, a disruptor — just like any change. Case in point, Waterstones, a bookseller, experienced serious supply chain disruptions affecting customers, staff, and authors after installing a new warehouse management solution.

So, it’s vital to be prepared for the change. Before a business adopts WMS software, it’s important to adapt the workflow accordingly. This involves having defined processes and user roles, adjusting location codes and the warehouse layout to the system’s standards, setting up all necessary hardware, and so on.

In addition, possible changes in operational needs should be kept in the equation: for example, new picking requirements were a key driver to invest in a new WMS for 36% of respondents in a survey.

It’s also critical to ensure warehouse staff are ready for the change. Personnel training is an important component of successful WMS implementation. Businesses must be sensitive to the risk of relying too heavily on automation and performance control in the way Amazon did in the UK, causing a wave of discontent among its warehouse employees — after all, successful WMS implementation is a balancing act between technology and humans.

And last but not least, it’s vital to choose a suitable system.

How to Choose the Best WMS Software for Streamlining Operations in Logistics

Choosing the wrong WMS can lead to decreased productivity, limited visibility, and downtimes — inevitably affecting every single participant in the supply chain. That’s why successful implementation starts with the right choice.

Here’s what we recommend paying attention to:

- Business type. An e-commerce business, for example, must make sure any new solution has the relevant feature set and integrates with Shopify, WooCommerce, or other e-commerce platforms used.

- Niche. A system for a food retailer will be different from that for a pharmaceutical business.

- Business size. A business of any size will benefit from a WMS. However, the requirements for such systems are different. For example, a small business with modest order volumes won’t need features like robotic order picking — unlike a large enterprise.

- Scalability requirements. A business with significant growth ambitions must be sure a new system will accommodate scalability needs. This avoids having to switch platforms as the business scales up.

- Ease of use. This factor should align with a company’s training capabilities. Businesses lacking the time and budget to teach personnel how to use a new solution should opt for a platform without a steep learning curve.

It might so happen that there’s no suitable solution on the market. Building a custom solution can be a decent alternative.

Our Experience in Streamlining Logistics with Warehouse Management Systems

Many businesses simply don’t have the in-house resources to build a custom warehouse management solution. In this instance, our logistics software development company may be the perfect solution — we can deliver a product from scratch, upgrade existing software solutions, or provide a consultation to ensure your current WMS is up to scratch.

At Django Stars, we have a solid grasp of the technologies needed to build a powerful WMS platform, including machine learning, computer vision, data science, data engineering, and virtual assistance. We can help roll out a platform that ideally mirrors and augments the workflow in any warehouse, aligns with training capabilities in organizations, integrates seamlessly with familiar solutions, and scales effortlessly — all within budget and timeline constraints. We can work both independently and as an integral part of a team.

Conclusion

Today’s supply chains are being challenged by the rise of the on-demand economy, labor shortages, and growing delivery expectations — raising important questions such as how does logistics reduce carbon footprint while meeting these demands. That’s why a robust WMS with extensive automation and analytics capabilities is the key prerequisite for any modern manufacturer, distributor, or retailer to succeed.

We specialize in cases where no suitable solution is available on the market and where businesses lack the resources to develop a custom one in-house. Our designers, engineers, QA experts, project managers, and business analysts are ready to assist, no matter how complex the case.

- Why do companies need warehouse management software?

- First, running a warehouse is in itself an extremely error-prone process. Second, many customers expect same-day or next-day delivery options, a situation aggravated by competitors constantly raising the bar for warehouse management standards. Third, global shipping volumes have drastically increased due to the rise of the on-demand economy.

- What are the key benefits of implementing warehouse management software?

- Implementing warehouse management software offers plenty of benefits. For example, a powerful WMS will boost productivity, increase order accuracy, facilitate efficient use of storage space, enable real-time inventory visibility, and increase employee satisfaction.

- Can warehouse management software integrate with other corporate systems?

- Yes, warehouse management software can integrate with various systems, such as ERP systems, CRM solutions, transportation management systems, e-commerce platforms, and beyond. Besides this, barcode and RFID scanners, conveyors, forklifts, and robots can also connect to some WMS.

- How much does it cost to implement a warehouse management system?

- The cost to implement a WMS will depend on its complexity, the level of our involvement, the type of expertise we outsource, the number of requirements, and more. Contact us for an accurate estimate.

- How long does it take to implement warehouse management software?

- Similar to the cost, the timeframes will vary from project to project, depending on complexity, the level of our involvement, the technology stack, requirements, and so on. For a more detailed cost breakdown, reach out to us — and we’ll discuss the project together.