What is Supplier Relationship Management (SRM)?

Stepping into the logistics arena without the proper Supplier Relationship Management (SRM) tools is like trying to solve a Rubik’s Cube in the dark. It’s possible, but it’s more complicated than it might be.

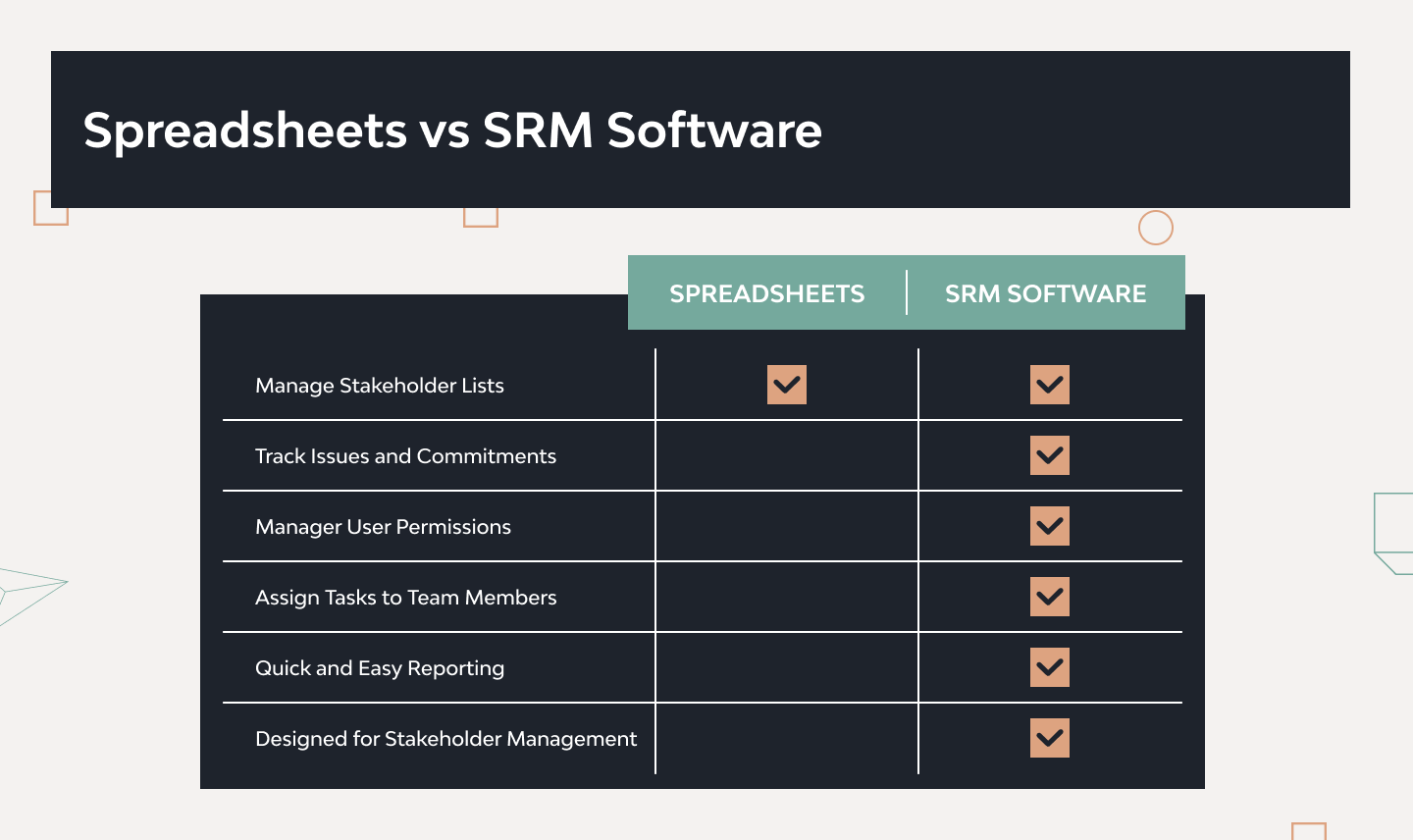

The logistics industry has been wrestling with the limitations of manual processes for many years. Imagine navigating through a maze of Excel sheets and a deluge of emails. It’s a path fraught with errors, inefficiencies, and missed opportunities for collaboration. What if I told you there was a lantern to light the way? It’s high time to talk about Supplier Relationship Management (SRM), the beacon that promises to illuminate the path and pave it with efficiency and automation. What are the key pain points solved by SRM software?

This article delves into how SRM emerges and transforms complex operations into streamlined processes. Through the lens of DjangoStars’ innovative solutions and real-life case studies, I’ll show you the transformative power of relationship management in supply chain in action, offering a glimpse into a world where logistics operations are managed and mastered.

Supplier Relationship Management Meaning

What is supplier relationship management? It is more than a collection of haphazard attempts to find suppliers for your organization and strike a deal with them here and now to solve your immediate sourcing problems. By SRM enterprises, we mean a systematic, structured, and proactive approach to establishing long-lasting relationships with suppliers, optimizing existing rapport with them, and minimizing risks related to this aspect of the business pipeline in many industries.

The ultimate goal of supplier relationship management is to set up and maintain an efficient, flexible, and stable supply chain whose clockwork functioning will benefit stakeholders and deliver maximum value to all parties involved. SRM goes beyond classical vendor management, which focuses on service-level agreements and contract compliance, or procurement operations that deal with ordering, invoicing, payments, and other transactional elements of purchasing. For SRM as a system, it is vital to foster strategic, collaborative partnerships with key suppliers.

Naturally, you can succeed in launching an efficient SRM system if you leverage a robust supplier relationship management platform in your efforts and have a clear vision of the steps to take during the SRM implementation routine.

Supplier Relationship Management Process: 6 Steps

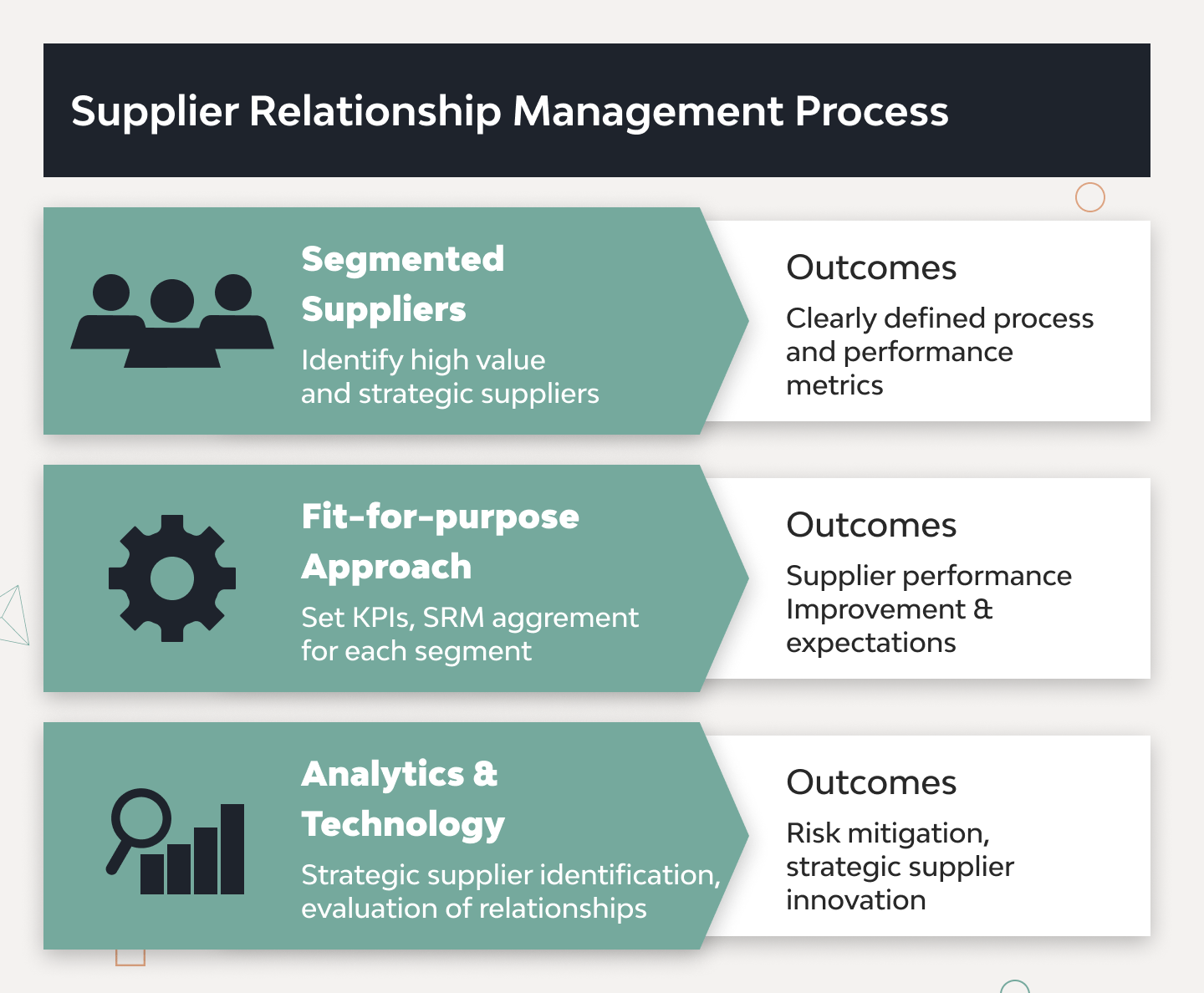

A standard supplier relationship management process encompasses six stages.

1. Supplier Segmentation

The first thing you should do is categorize your suppliers into groups, using their business importance, value, and risk as yardsticks. The typical roster of such classes includes strategic, average, bottleneck, and non-critical partners.

2. Setting Objectives

It’s not only about the goals you plan to achieve. Reaching each milestone in each shop floor aspect (quality, cost, delivery speed, innovation, etc.) should be reflected in transparent metrics. They will allow you to monitor how your partners fulfill contract stipulations and hold them accountable if they fail to do so.

3. Building Relationship Strategies

With all preliminary parameters on your table, you craft a comprehensive collaboration roadmap. Basically, it should outline an image of your ideal supplier scenarios and describe what you need to do to implement them in real life.

4. Strategy Execution

This is when your supplier relationship management process enters its execution phase. Here, you engage with your suppliers, set up convenient for all parties communication lines, arrange feedback loops, and share insights to keep the supplier relationship management (SRM) pipeline ticking.

5. Performance Measurement

You should track the KPIs established and agreed upon at stage 2 as long as your partnership with the vendor lasts. In this way, you will be able to pinpoint current and potential problems and take steps to eliminate them today or prevent them down the line.

6. Improving Supplier Relationships

However satisfactory your relationships with suppliers may be, there is always room for improvement. If you don’t let yourself rest on your oars, you can maintain the dynamics of your cooperation with partners and ensure its alignment with your company’s shifting needs.

When you follow this algorithm closely, you can maximize the advantages SRM promises.

Benefits of Supplier Relationship Management

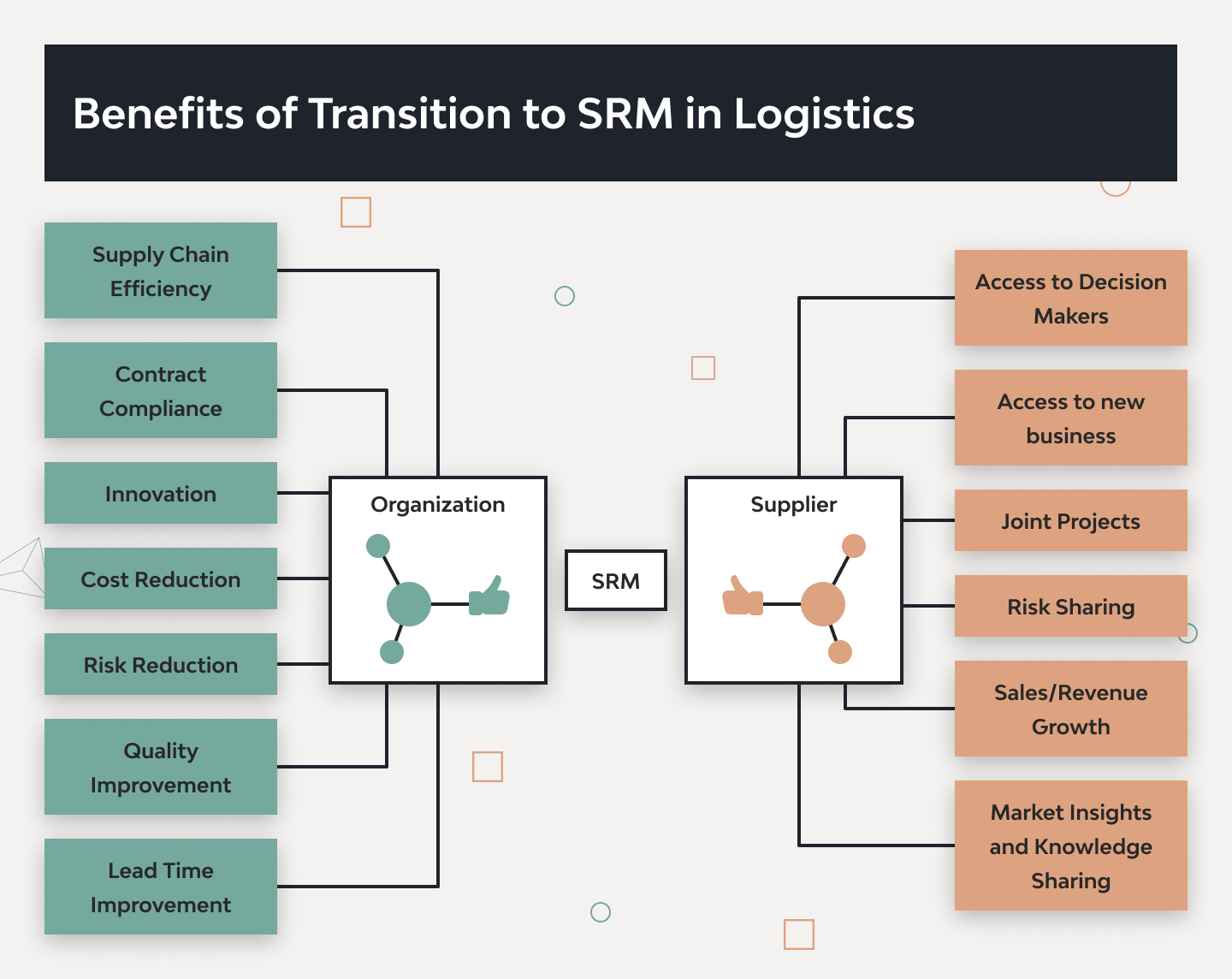

Workmanlike development and meticulous implementation of supplier relationship management strategies usher in numerous supplier relationship management benefits.

1. Cost Reduction

Establishing strategic partnerships with suppliers paves the way for bulk discounts, lower prices, favorable payment terms, and other perks that organizations can negotiate when signing long-term contracts. Moreover, hidden costs related to prolonged procurement cycles, waste, and switching to another supplier also plummet.

2. Greater Visibility and Transparency

All processes within your supply chain are registered in the SRM solution your organization uses, providing a 360-degree view of your business pipeline. Such visibility can be enhanced by leveraging GPS trackers on transportation vehicles, enabling personnel to monitor each delivery step and the movement of goods in real-time.

3. Faster Supplier Collaboration

The importance of supplier relationship management rests (among other factors) on the instant reaction of parties to the requests of their partners. Robust SRM tools utilizing open communication channels enable them to coordinate their efforts 24/7 and solve problems on the fly.

4. Risk Mitigation

All supplier relationship management strategies involve risk management considerations. Vibrant communication between partners and proactive contingency initiatives mitigate possible supply disruption threats, enable the timely detection of shortages and delays, and allow for the swift addressing of issues before they escalate.

5. Enhanced Supplier Responsiveness

Supplier relationship management best practices presuppose keeping partners informed about your fluctuating circumstances and needs. Seeing such an attitude, they are likely to respond in kind. Thus, staying on the same page with each other, you display coordinated teamwork where lightning-quick exchange of information, insights, and messages becomes a game-changer.

6. Sustainability and Compliance

When your relationships with suppliers are structured and systemic, you have more opportunities to control your partners’ compliance with legal and environmental standards and prevent any violations beforehand. Such a capability minimizes the risk of legal disputes and fines that stakeholders may incur.

7. Insight into Suppliers’ Capabilities

When staying with your partner for a long time, you get to know them better. So, you can discover additional cooperation opportunities, the expertise in logistics you lack, or a positive experience in handling regulatory red tape. Thus, the value you gain from your collaboration goes beyond the shop floor processes you are involved in.

Alongside weighty fortes, supplier relationship management is fraught with some pitfalls.

Supplier Relationship Management Challenges

What are the most serious obstacles on the way to a smooth supplier relationship management process?

1. Lack of alignment

Focusing on their own goals, companies sometimes forget that what they consider of paramount importance may be only a sideshow or an afterthought for their partners. The lack of alignment may also stem from a failure to stay on the same page. In any case, you should stay in touch with your partner to remove possible misunderstandings and understatements.

2. Supplier diversity issue

Cooperating with several vendors gives you flexibility and minimizes supply chain disruption risks, but requires going the extra mile in supplier relationship management (SRM). Sticking with only one supplier is simpler and more beneficial financially, but if something happens with the partner, you are in a pickle. You should try to strike a balance between the two strategies.

3. Risk & continuity gaps

Whenever a supply chain is broken (for any reason), organizations on the receiving end suffer business workflow continuity gaps. Diversifying supply chains, staying in the know of suppliers of your suppliers’ condition, and maintaining proactive communication with your partners can help mitigate such threats.

4. Visibility challenges

Even in the most cooperative relationships, you can’t get 100% visibility into all aspects of your collaboration, especially those pertaining to your partner organization. Innovative supplier relationship management solutions and technologies (like GPS tracking, for instance) can be a good crutch in addressing this problem.

You can utilize SRM systems efficiently once you learn to successfully handle these challenges and realize where they can bring maximum value.

Supplier Relationship Management Logistics Use Cases

There are several applications of supplier relationship management systems in the logistics realm.

- Operational and efficiency use cases. By onboarding an SRM (supplier relationship management) system, enterprises automate and streamline repetitive tasks, simplify data management, optimize costs, enhance supply chain visibility, facilitate procurement, and improve productivity manifold.

- Collaborative use cases. In collaboration with partners through SRMs, organizations can track supplier performance, assess their reliability, mitigate disruption risks, increase resilience and brand loyalty, and work together on workflow quality augmentation and meeting delivery standards.

- Compliance and sustainability use cases. The implementation of supplier relationship management examples holds significant potential for achieving sustainability targets. Besides, centralized supplier management is a perfect tool for ensuring regulatory compliance across all shop floor operations.

Check out how DjangoStars helped implement an AI-fueled SRM system for a garbage disposal enterprise.

Transforming Garbage Disposal with AI: A DjangoStars Case Study

Our adventure in reshaping the garbage disposal sector began with a dream shared by us and a forward-thinking client. This dream set us on a path to meticulously plan our project, piece by piece, during an in-depth discovery phase. Together, we crafted a vision for a project that was nothing short of revolutionary.

Three Core Objectives:

1. An Intelligent AI Engine

Our first challenge was to implement route optimization integration through an AI engine capable of crafting driving routes in real time while adapting to day-to-day changes and resource availability. This technological marvel would ensure that drivers always take the most efficient paths. It leads to saving time and reducing costs in logistics using SRM.

2. Web and Mobile Applications

Next, we focused on creating user-friendly web and mobile applications for managers and drivers. These platforms were designed to introduce logistics document management automation and personalization previously unseen in the industry. They streamlined every aspect of the garbage disposal process.

3. A Seamless System for All

The crown jewel of our project was a comprehensive system that connected admins, managers, and drivers in a seamless digital environment. This solution promised to simplify planning, optimization, and execution. It made the garbage disposal process as smooth and efficient as possible.

The Bottom Line

We’ve dived into the dynamic world of Supplier Relationship Management (SRM) systems and highlighted their role in fostering collaboration, ensuring accuracy, and enhancing overall supply chain visibility.

Through the lens of a DjangoStars case study, we’ve explored the supplier relationship management best practices and real-world application of AI in revolutionizing the garbage disposal process, api integrations for logistics industry, making it more intelligent, efficient, and transparent.

DjangoStars is at the forefront of this innovation, blending deep expertise with custom logistics software development. Our journey began with a US startup driven to redefine the garbage disposal industry. This partnership highlighted our capacity to dream big.

- What are the biggest challenges logistics teams face relying on manual processes like Excel and email?

- The major hurdles include inaccuracy due to human errors, limited visibility into the supply chain, inefficiency from time-consuming manual entries, and a lack of collaboration across the network of suppliers and stakeholders.

- How does SRM help improve communication and collaboration with suppliers in the logistics process?

- SRM systems enhance communication and collaboration by providing a centralized platform for information sharing, real-time updates, and streamlined workflows, ensuring all parties are aligned and informed throughout the supply chain process.

- What key functionalities of an SRM system benefit logistics operations the most?

- Key functionalities include strategic supplier segmentation, performance management, risk management, collaborative innovation, enhanced communication and transparency, and efficient contract management. They are all designed to optimize logistics operations and supplier relationships.

- What key steps should businesses take to successfully implement and integrate an SRM system into their logistics operations?

- Businesses should conduct a thorough needs assessment to identify pain points and desired functionalities, carefully evaluate and get ready for choosing the right SRM system, ensure smooth data migration and system integration, prepare employees through change management and training, and engage in continuous monitoring and improvement to adapt the system for optimal performance.

- How can transitioning to an AI-powered SRM solution, like the one developed by DjangoStars for garbage disposal management, benefit logistics companies?

- Transitioning to an AI-powered SRM solution can significantly benefit logistics companies by automating and optimizing route planning, enhancing operational efficiency, reducing costs, and improving decision-making through real-time visibility and analytics. Such a solution enables a more agile, responsive, and customer-focused approach to logistics management.