10 Logistics Trends in the Supply Chain Industry 2026

Valued at $25.6 billion in 2026, it is safe to say that the logistics and supply chain industry is entering a new phase this year. One shaped by direct customer expectations, global trade shifts, and more technology in the workplace. Companies are moving away from rigid, manual processes and adopting smarter, more connected systems for faster, more personalized, and to-the-point operations.

The latest logistics trends that drive the niche make or break your warehousing efficiency, transportation costs, order productivity, and overall service quality. Understanding what underlies the future of logistics can help logistics providers, manufacturers, and retailers stay competitive, cut on operational risk, and achieve more flexibility with their supply chains.

Let’s take a peek — in this article, we’ll explore the top 10 logistics industry trends 2026 that are redefining how goods move across the world.

List of top 10 logistics industry trends in 2026

- AI and Machine Learning in logistics

- Automation and robotics

- Sustainable and green logistics

- Blockchain for transparency

- Advanced data analytics

- Digital supply chain platforms

- E-commerce-driven logistics

- Resilient and agile supply chains

- Internet of Things (IoT) integration

- Human-centric logistics

AI and Machine Learning in logistics

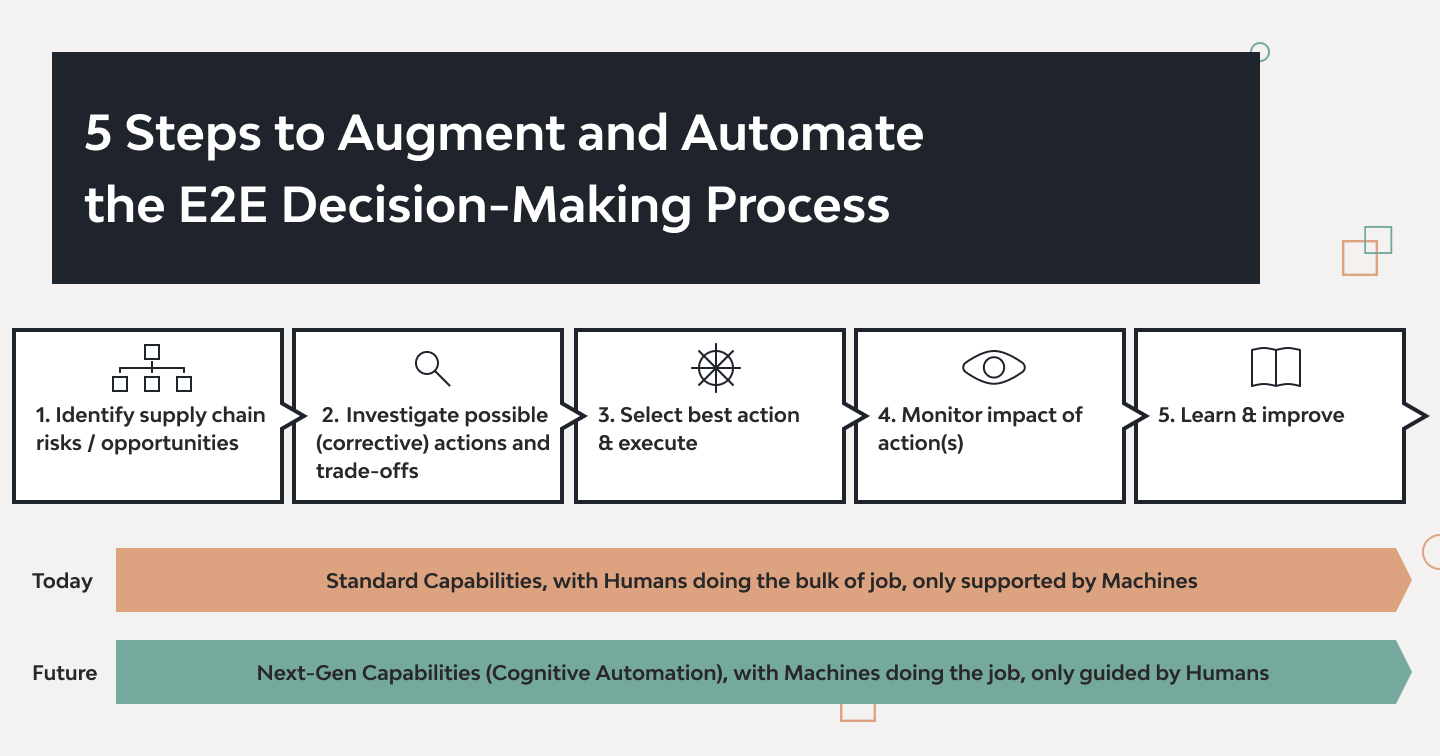

Artificial Intelligence has come a long way in its integration potential for logistics and, coupled with Machine Learning techniques, now helps shippers analyze data, automate item decisions, and optimize staff tasks.

AI/ML integrations enable demand forecasting at high accuracy, allowing to predict customers’ needs, pick optimal shipment routes, and avoid any disruptions. With that in hand, an AI/ML-equipped warehouse cuts operational costs and boosts delivery speed dramatically.

For example, carriers can use AI for smart real-time route planning, while warehouses use machine learning to predict inventory needs, and support teams automate responses through AI/ML-based chatbots.

Ultimately, routing decision-making based on the latest fruits of AI improves any logistics operator’s efficiency while getting rid of senseless operations across the entire supply chain.

Automation and robotics

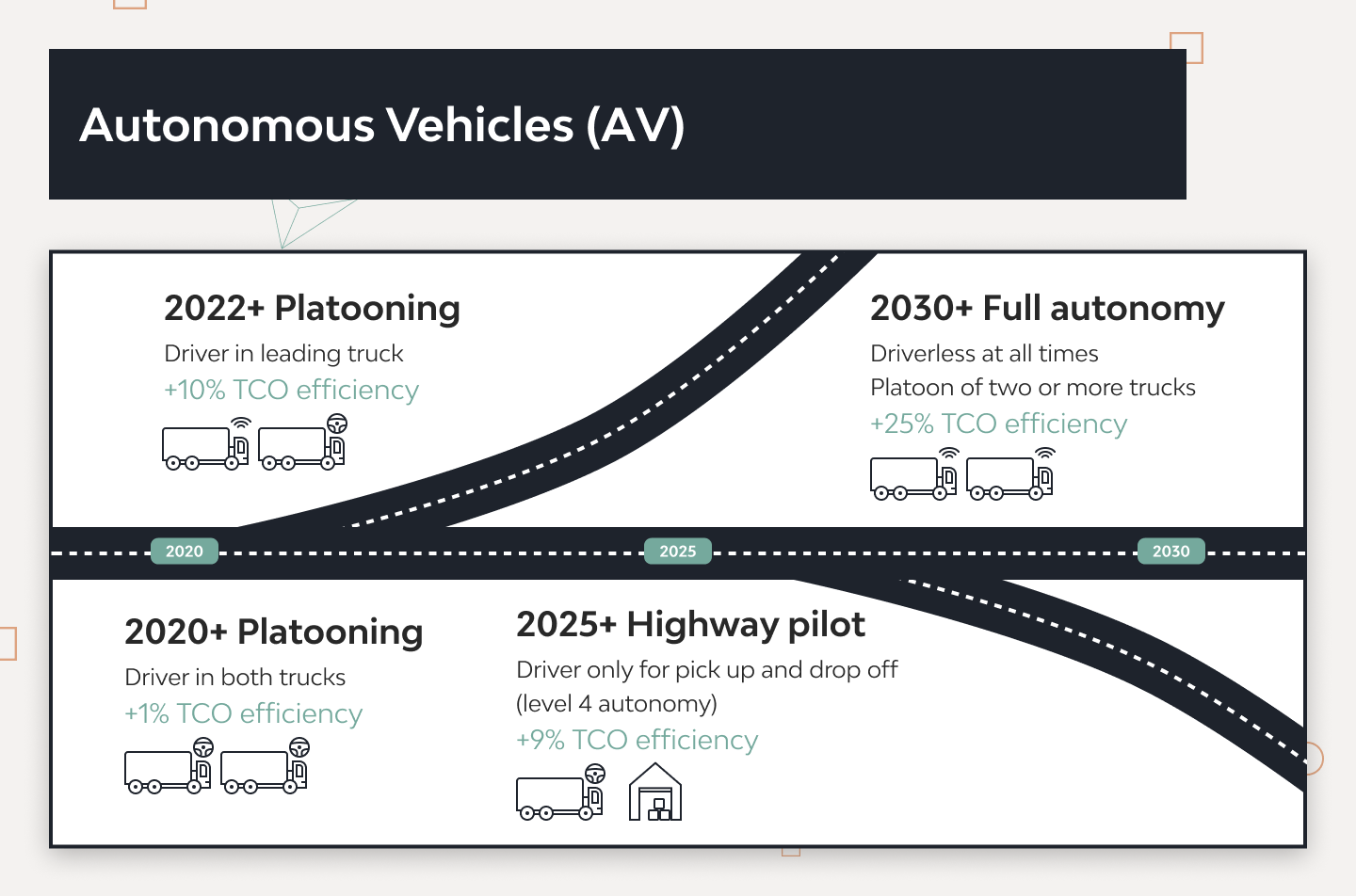

One of the main emerging logistics technology trends is thorough automation with the help of warehousing robots that can handle repetitive and heavy lifting manual tasks, such as on-site picking, sorting, packaging, and movement of materials.

Coupled with parent AI/ML platforms, implementing robotics in a warehouse is a major step towards competitive tech innovation. The robots perform manual tasks faster, don’t need days off, and demonstrate almost errorless performance in high-volume logistics environments.

Gradually, autonomous forklifts, robotic picking arms, and automated conveyor systems are becoming the new norm in active warehouses. When working alongside human specialists, autonomous mobile robots keep humans safer and less fatigued.

All in all, robotics boosts warehouse productivity and reinforces the reliability of operations while potentially minimizing manual workload.

Sustainable and green logistics

Green logistics is about minimizing environmental impact and the eventual carbon footprint from transportation, warehousing, and packaging, mostly through tech optimization means.

Sustainability initiatives are among the forward-minded trends in logistics, focused on reducing fuel usage rates, lowering harmful emissions, and battling the carbon footprint through tech. They also help companies meet regulatory compliance while keeping consumers satisfied and more trusting.

To achieve eco-friendlier, greener operations in warehouse and logistics management, you can electrify delivery fleets and use recyclable packaging for inventory items. By investing in AI/ML and other tech for route and logistics optimization, you can cut fuel waste, making your logistics greener still.

In the long run, sustainable logistics can help reduce both harm and costs, while boosting your brand reputation as a cleaner provider.

Blockchain for transparency

Another huge aspect of logistics to manage is data, and blockchain allows storing it in a ledger with tamper-proof security — nobody can change the data in any way once it’s stored on-chain.

Supply chain data is very sensitive, dynamic, and valuable as Business Intelligence. Keeping it in a blockchain ledger enables you to fully trace products from origin to delivery, boosting compliance and giving you an upper hand in battling fraud and scams.

For a real-world instance, food supply chains commonly use blockchain to verify the sourcing of goods. And freight networks can use it to store shipment documentation, without risks of tampering.

Once integrated with your logistics platform, blockchain will enable full accountability of all assets, from data to physical.

Advanced data analytics

Data analytics gathers large datasets and reads into operational and customer data to give you business insights for optimizing workflows, managing waste, and planning cost-efficient operations ahead of time.

With in-depth analytics tools, carriers and warehouse managers are enabled to plan inventories based on direct insights, cost forecasting, and real-time logistics analyses. AI/ML-based analytics will help uncover inefficiencies across the board and solve delivery delays.

By adopting data-focused logistics trends, you can refine operations through the analysis of delivery times, performance of individual suppliers, fluctuations in demand, and seasonal profitability.

The more data-driven your logistics decisions are, the greater the efficiency you can gain, while the precision of the insights will also lower operational risk.

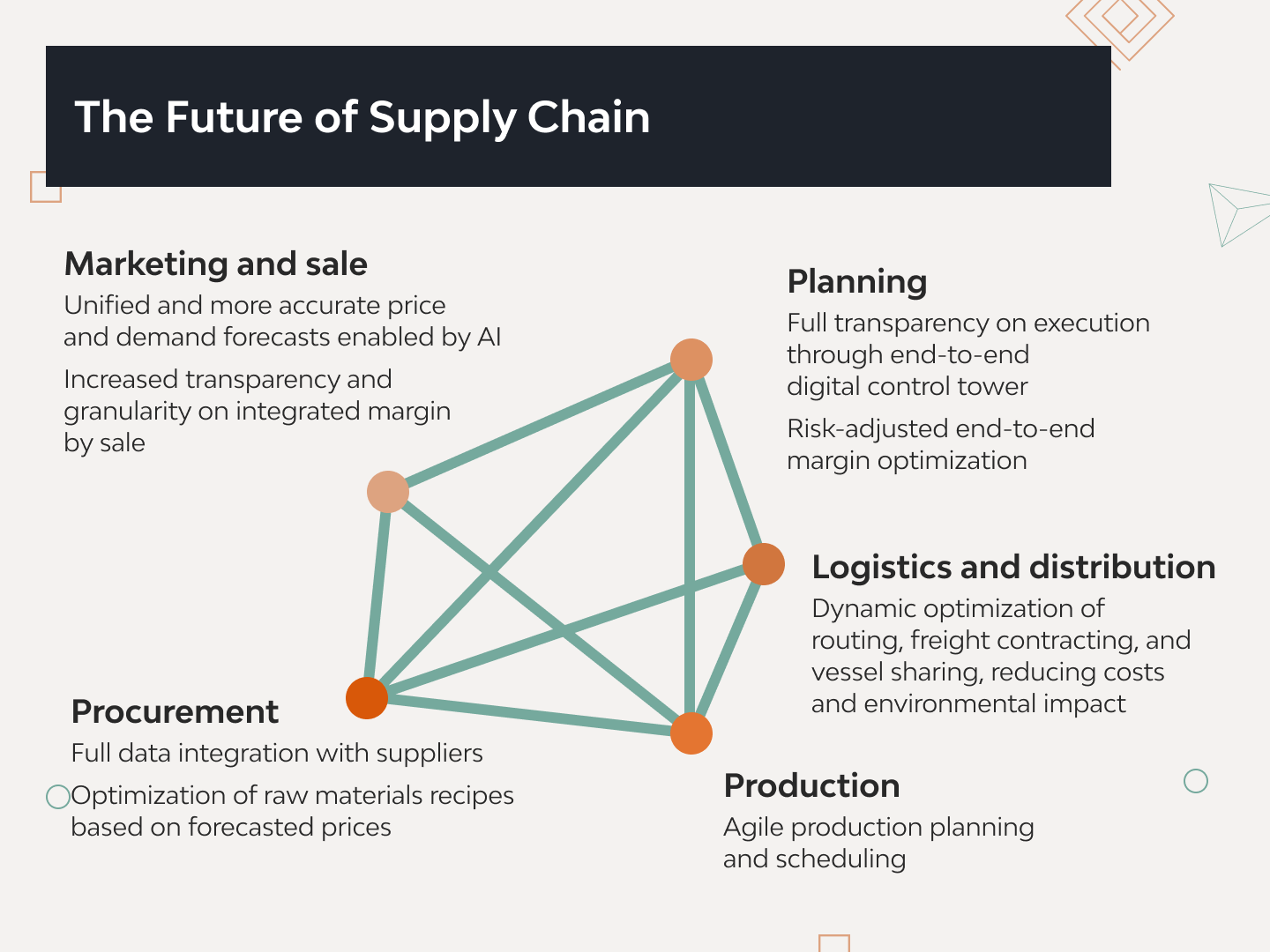

Digital supply chain platforms

If AI/ML helps dig up the data and process it, and analytics to read into it and gain insights, then digital platforms are the hubs that centralize tracking, coordination, and communication among suppliers, carriers, and warehouses.

A specialized online, cloud, or desktop and mobile platform syncs things up and provides visibility into all processes and fine details of logistics. It eliminates manual paperwork, keeps employees in instant touch, and enables real-time adjustments of supply chain operations.

The most common types of supply chain platforms leveraged today are cloud-based TMS, WMS, or ERP systems. These can be used to keep stakeholders connected through a shared digital workflow.

A centralized platform will boost the aspect of collaboration and logistics network management in a shipper’s operations.

E-commerce-driven logistics

E-commerce is a phenomenon that has given rise to tools reshaping logistics networks to support faster, smaller, and more frequent deliveries — ultimately enhancing customer convenience.

The demand for same-day or next-day delivery is currently peaking, reflecting customers’ expectations for speed and convenience. E-commerce approaches can be applied in the management of inventories, orders, and deliveries, breaking bulk operations down into smaller items for quicker profits.

For instance, a carrier or logistics provider can connect with micro-fulfillment centers, use on-demand courier services, and integrate AI-driven warehouse picking systems — the latest e-commerce logistics trends.

So if you are looking to maintain a competitive logistics strategy, you should prioritize speed, flexibility, and last-mile delivery, all of which can be achieved through e-commerce tech.

Resilient and agile supply chains

One of the overarching logistics trends is keeping a supply chain agile in its responses to issues and more resilient to market fluctuations through technology and workflow optimization.

Today’s global markets are very uncertain and fluctuate a lot, and you need to adapt the supply chains to disruptions and dynamics like supplier failures, shipping delays, or sudden changes in demand. Commonly, it’s better done in real-time.

To gain flexibility in their supply chains, companies can diversify suppliers, use buffer inventory models, and develop rapid rerouting protocols. They can also use scenario modeling to prevent disruptions and turn more to nearshore operators.

A shipper’s logistics resilience is their saving grace in times of insatiable global market relations and risks.

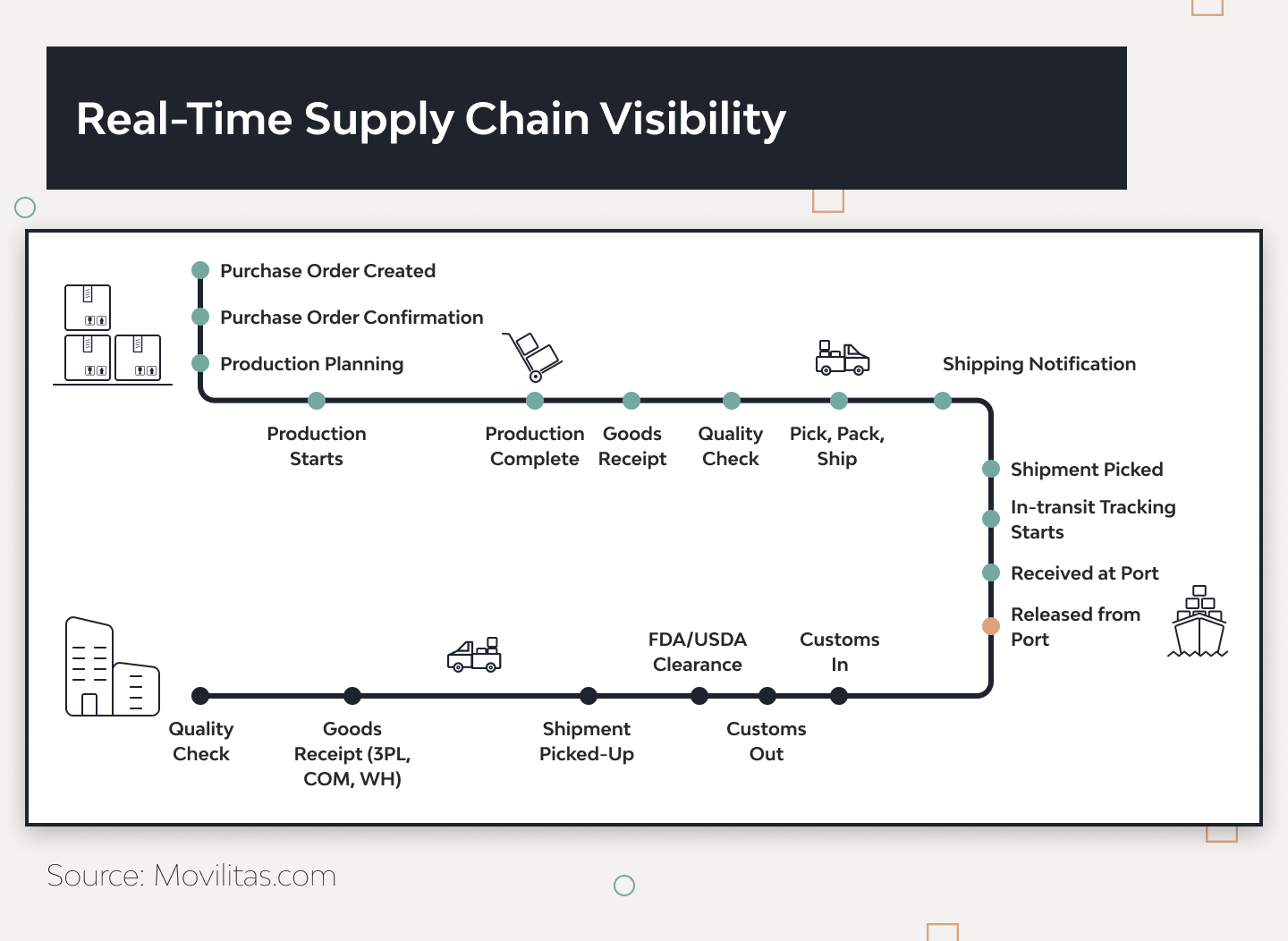

Internet of Things (IoT) integration

IoT enables full centralization and synchronization of devices, operations, and tasks in warehouses, fleets, and logistics operations across the supply chain.

IoT sensors monitor and transmit real-time data from vehicles, objects, and shipping containers. They are interconnected into a single IoT network, giving managers instant visibility of inventory, equipment and its state, and tracked shipments.

To set an IoT network in motion, companies use GPS trackers, smart pallets, and temperature sensors to track shipments and monitor their storage conditions. The monitoring can be done both on-premise and on the go, depending on the extent of your integrations.

All in all, IoT provides a collected image of all operations and moving parts in a shipper’s workflow, uncovering more optimization insights still.

Human-centric logistics

One of the more novel trends in logistics and supply chain management is human-centric optimization, which advocates technology but prioritizes worker experience, training, and safety alongside automation.

The benefits of automation and tech can easily overshadow human priorities, which human-centric logistics aims to turn around and focus more on mutual benefits. It’s also more important than ever to keep employees engaged with the technology to see the real results of human-robot collaboration.

Workers in warehouses, fleets, and logistics operations can use worker-assist technologies like wearables, AR instructions for smartphones, and real-time space outlines. More visual instructions, feature interactions, and hands-free operations equal higher, faster live performance.

Remember — live employees are the real cornerstone of logistics efficiency, and your tech should enhance, not replace, the workforce.

Conclusion

Recent advances in data science and engineering are driving a seismic shift in the future of freight transportation. Accelerated by customer demand for sustainability and visibility, these advances are revolutionizing the logistics industry and presenting opportunities for new competitors to enter the market.

For example, the DRG Solutions team will keep an eye on the following trends in logistics and supply chain management in the near future: AI, supply chain agility, automation, green logistics, supply chain visibility, and addressing labor shortages. Embracing technology and sustainable practices will be key for companies to succeed in an increasingly competitive logistics landscape.

To succeed, transportation and supply chain companies must deftly navigate new logistics trends. When adopted properly, the above logistics industry trends for 2026 can improve operations and secure a company’s position in the market, delivering a quick and impressive ROI.

Our tech experts constantly research the market so that we can offer clients the most optimal custom supply chain management software solutions for their development needs. Our successful logistics use cases demonstrate how using best practices with the latest technologies helps businesses reach a wider audience and improve their bottom line.

Django Stars’ experts have your back. Contact us, and we’ll happily prepare your logistics business to navigate turbulent markets.

- What are the key logistics trends in 2026?

- The main logistics and supply chain management trends to look out for in 2026 include AI/ML, automation and robotics, sustainable and eco-friendly operations, blockchain, in-depth data analytics, digital supply chain platforms, e-commerce approaches, operational agility and resilience, IoT, and more human-centric practices.

- How does AI impact the logistics industry?

- Artificial intelligence can enhance logistics visibility, optimize route planning, and provide predictive analytics to facilitate decision-making. This leads to substantial cost savings and improves operational transparency.

- What’s the role of IoT in modern logistics and supply chain management?

- IoT devices and sensors can collect data from various links in the supply chain, including warehouses, vehicles, and products. These data can monitor environmental conditions, track assets, optimize inventory management, and enhance supply chain visibility.

- Which of the current IT logistics trends in supply chain management requires the least investment?

- Leveraging automation typically requires a smaller investment compared to other tech trends. Still, it has a good ROI and can perform recurring, time-consuming activities like sending invoices, filling out forms, and handling simple customer requests.

- Why is sustainability important in logistics?

- Logistics and related operations, like warehousing, high electricity consumption, manufacturing-grade equipment use, and fleet movements, can be very emissive and generate a lot of waste. Being sustainable is critical to minimizing the carbon footprint.

- What is a Digital Twin, and how does it improve supply chain visibility?

- Digital twins are the digitized replications of your supply chain down to a T. Creating a digital twin provides a full view of supply chain tasks, milestones, and details in a convenient virtual environment. It can be used for data analytics, predictions, risk analysis, and modeling.

- How does the rise of Autonomous Mobile Robots (AMRs) affect the human warehouse workforce?

- Autonomous mobile robots are among the main trends in logistics, and some human employees can feel the effect, which can be of two types: facilitation of manual tasks and growth or potential replacement. However, human-centric logistics is another trend that may still turn things around.